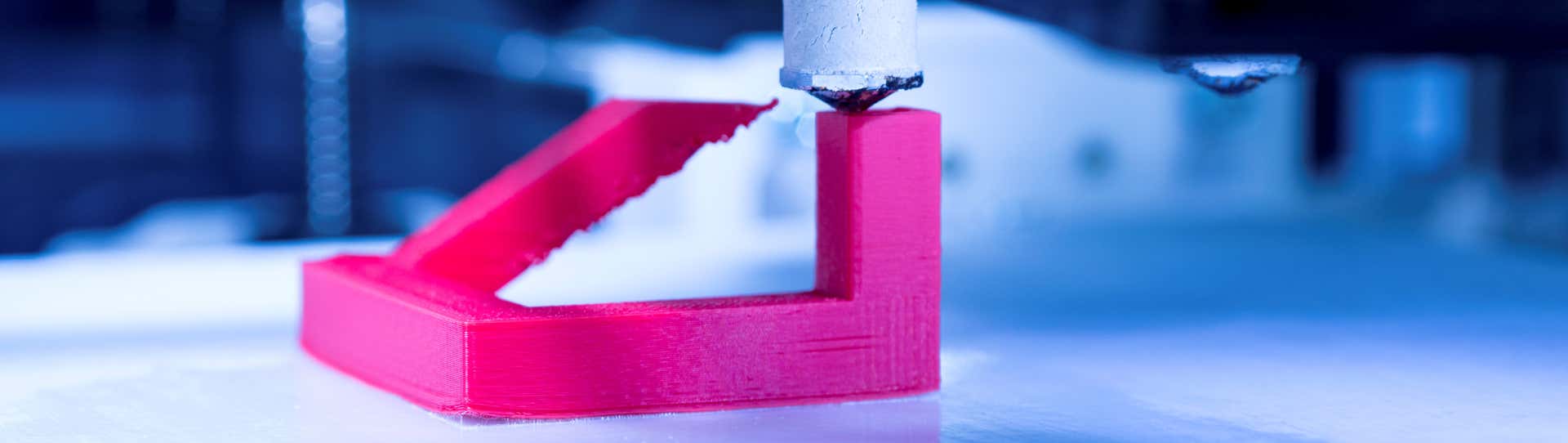

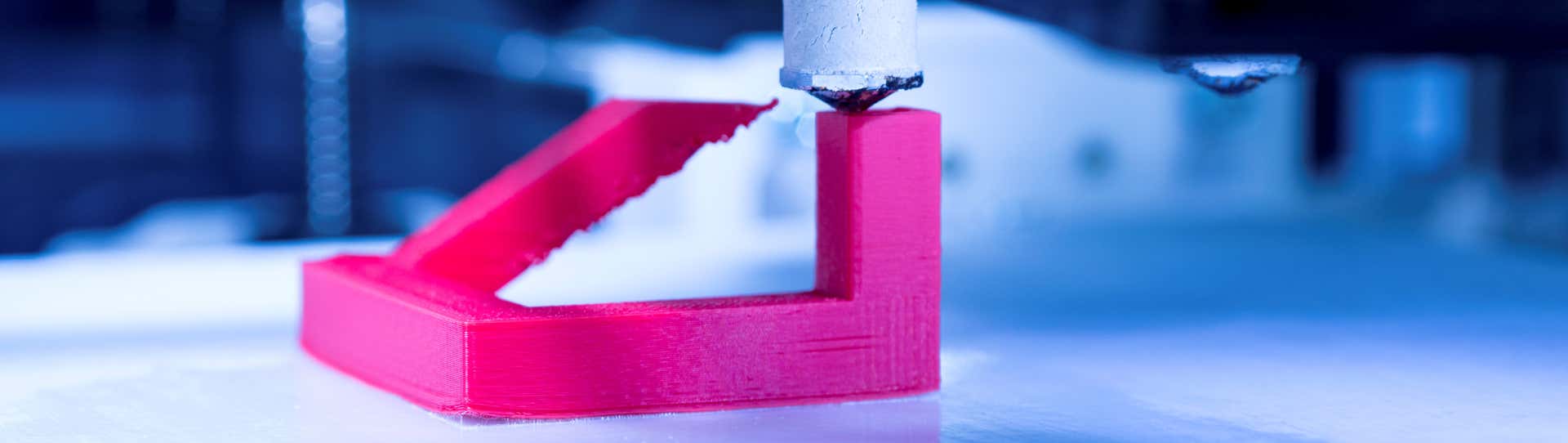

Fused deposition modeling

Fused deposition modeling (FDM) is based on the principle of material extrusion where a thermoplastic filament is drawn through a nozzle, heated to its melting (or glass transition) point and then deposited layer by layer. Once deposited the thermoplastic layer fuses with the layer below, cools and hardens. This process is repeated until the 3D structure is complete. The most common polymer used for FDM is acrylonitrile butadiene styrene (ABS) but polycarbonate (PC) and polyetherimide (PEI) are also used. As the applications for 3D printing and fused deposition modeling increase, there is a necessity to develop novel polymers with unique mechanical properties that are also printable. Material characterisation is critical to this development process for assessing the melt characteristics and structure of the polymers, as well as the mechanical properties of the printed part.

The behavior of the melt and mechanical properties of the finished part are related to the molecular structure and molecular weight distribution of the feedstock material. Hence it can be important to validate these properties to ensure a consistent supply of raw material or to assist in the development of novel materials. Gel Permeation Chromatography (GPC) is a useful tool in this regard since it can determine molecular weight distribution but also structural parameters such as molecular density and degree of branching.