Iron production

To produce high-quality iron and steel at minimal cost, you need efficient metal analysis processes – with the lowest possible fuel and energy use – and consistent material streams. Not only that, but optimized processes and materials can also help you reduce costs and meet environmental goals. For instance, innovative new process monitoring technologies will help enable new iron production methods that can be used to achieve CO2-free steel.

But, in order to predict and optimize your material’s behavior, you need to monitor it continuously at all process stages – and respond quickly to the results. With Malvern Panalytical’s industrial solutions, you can analyze the mineralogical, elemental, structural, and particle size composition of iron sinter, pellets, direct-reduced iron, and steel within minutes – for truly futureproof operations.

Your solutions:

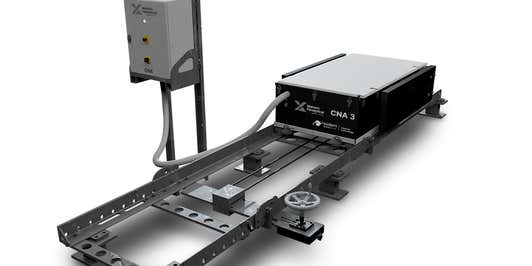

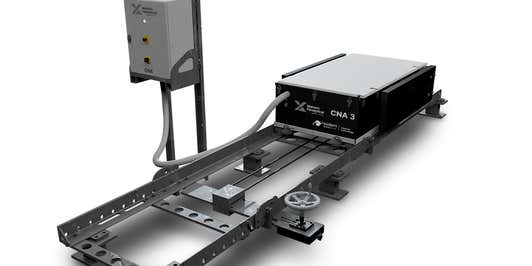

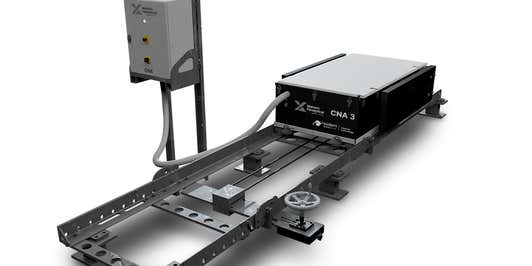

Efficient, safe, sinter production starts with ensuring your sinter plant gets the best input material. To ensure this, you need to monitor the elemental composition of your intermediate raw materials and mixtures. With our high-throughput neutron-based CNA3 Sinter analyzers, we make this easy.

But that’s not all: to prevent time-consuming, expensive wet chemical & physical tests and achieve faster counteractions, it’s also essential to monitor the phase composition and process parameters of the iron sinter itself. These parameters can include Fe2+, FeO, basicity, low-temperature degradation, sinter strength, and reducibility. Our unique XRD solutions can analyze all these properties, and our XRF solutions can also monitor your sinter’s elemental composition.

By monitoring the particle size, elemental composition, and mineralogical composition of your pellet feed, you can predict pelletizing conditions, such as compressive strength, more easily – and optimize these properties for high-quality iron ore pellets. With our on-line laser diffraction solutions, conveyor-belt elemental analyzers, and lab-based XRD and XRF solutions, carrying out this analysis is easier than ever.

Also known as sponge iron, direct-reduced iron (DRI) is produced by reducing iron ore using a gas produced from natural gas or coal. To make this process as efficient and safe as possible, the metallic iron content, metallization, total carbon content, mineralogical phase content, and elemental composition must all be monitored. Our X-ray diffraction solutions and X-ray fluorescence spectrometers analyze these parameters in minutes.

When it comes to steelmaking, rigorous process and quality control is essential – for both your raw materials and your final products. This requires rapid, accurate chemical analysis, as well as microstructural characterization of your metals and alloys. And this analysis has to cause minimal disruption to production. At the same time, there’s also mounting pressure from consumers and regulatory bodies for steelmakers to work toward sustainability goals such as CO2-free steel.

Our XRF and XRD instruments, along with our calibration and automation solutions, help steelmakers meet this challenging set of demands.