Aeris Guía de usuario

Version number: 7

Discover how Aeris XRD transforms materials analysis across mining, metals, and more. Learn more

Learn more

Looking for more information?

To request a quote, more information or download a brochure select an option below.

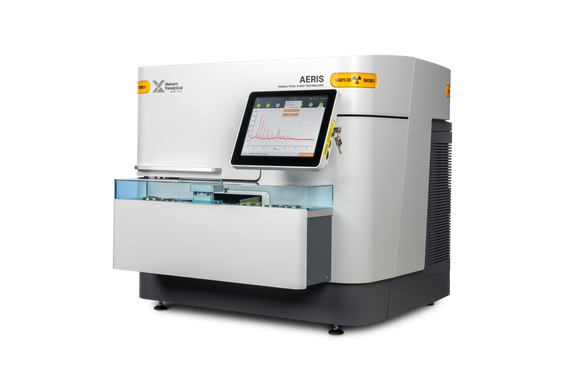

The Metals edition of Aeris is a benchtop X-ray diffractometer for rapid and reliable analysis of sinter, direct reduced iron and retained austenite.

Aeris is fully automatable and can easily be incorporated in industrial production control.

The Metals edition of Aeris is your partner at every stage of the production process, from raw material to the final product

X-ray Diffraction (XRD) is a key technology at every step of the steel making process. It is a valuable tool for rapid and accurate materials characterization of raw and intermediate materials employed in the steel making process (such as iron ore, sinter and direct reduced iron).

XRD is also ideal for quality control of the final products as it provides fast and precise quantification of metal phases such as retained austenite.

Rapid analysis minimizes feedback loops and allows early intervention for process optimization. Typical measurement times of Aeris are less than 10 minutes per sample.

Uptime of the analytical equipment is key for reliable process control. From the ground up, Aeris has been designed for maximum uptime.

The most intuitive X-ray diffractometer: with a built-in touch screen your results are always just a few taps away.

| Sample loading | External sample loading |

|---|---|

| Sample holders | Variety of full-sized sample holders capable meeting all requirements |

| Sample changing | Choose between a manual loading dock, 6-position sample changer, or 67-position high-capacity sample changer |

| Automation | Compatible with automation integration |

| Wavelength | Cu / Co |

|---|---|

| Tube setting | From 300 W to 600 W options in 30 kV or 40 kV setting |

| Tube housing | Patented design with Corrosion-resistant incident smart beam path technology (CRISP)

CRISP technology prevents corrosion in the incident beam path caused by X-ray induced ionized air. Patent no. US 8437451 B2 |

| Base configuration | Vertical goniometer, coupled and decoupled θ-θ, samples always horizontal |

|---|---|

| Geometry | Bragg-Brentano, Transmission, Grazing Incidence |

| Radius | 145 mm |

| Maximum 2θ range | -4° < 2θ ≤ 142° (with scanning detector and full active length) |

| Angle positioning | Direct optical position sensing (DOPS3) with lifetime positioning accuracy |

| Scan Speed | Max 2.17°/s |

| Resolution | < 0.04° 2θ on LaB6 (with 0.01 rad Soller slits) |

| 2θ linearity | < 0.04° 2θ |

| Smallest addressable increment | 0.001 ° |

| Spinning | Choice of spinner stages |

|---|---|

| Non-ambient | Heating stage option (BTS-500, BTS-150) |

| Exchange of stages | Alignment-free PreFIX exchange of stages |

| Special stages | On request (manual, MPSS, In-Situ) |

| Detector | Choose between the PIXcel1D, PIXcel3D and 1Der detectors |

| Dimensions | 690 x 770 x 786 mm |

|---|---|

| Dust protection | Closed system with external sample loading |

| External cooling water supply | Not needed |

| Compressed air supply | Not needed |

| Power Supply | 100 – 240 V, single phase |

| Computer | Internal instrument PC |

| Operation | Intuitive user interface with 10.4” touch screen |

| Interface | LAN, USB, HDMI |

Version number: 7

Version number: 8

Version number: 6

Version number: 7

Version number: 8

Version number: 8

Version number: 8

Version number: 2

Version number: 4

Version number: 3

Version number: 2

Version number: 4

Version number: 2

OmniTrust software update v1.7a

OmniAccess

OmniTrail

More information can be found in the Release and Installation Notes.

OmniAccess

OmniTrail

More information can be found in the Release and Installation Notes.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

The Metals edition of Aeris is a benchtop X-ray diffractometer for rapid and reliable analysis of sinter, direct reduced iron and retained austenite.

Aeris is fully automatable and can easily be incorporated in industrial production control.

The Metals edition of Aeris is your partner at every stage of the production process, from raw material to the final product

X-ray Diffraction (XRD) is a key technology at every step of the steel making process. It is a valuable tool for rapid and accurate materials characterization of raw and intermediate materials employed in the steel making process (such as iron ore, sinter and direct reduced iron).

XRD is also ideal for quality control of the final products as it provides fast and precise quantification of metal phases such as retained austenite.

Rapid analysis minimizes feedback loops and allows early intervention for process optimization. Typical measurement times of Aeris are less than 10 minutes per sample.

Uptime of the analytical equipment is key for reliable process control. From the ground up, Aeris has been designed for maximum uptime.

The most intuitive X-ray diffractometer: with a built-in touch screen your results are always just a few taps away.

| Sample loading | External sample loading |

|---|---|

| Sample holders | Variety of full-sized sample holders capable meeting all requirements |

| Sample changing | Choose between a manual loading dock, 6-position sample changer, or 67-position high-capacity sample changer |

| Automation | Compatible with automation integration |

| Wavelength | Cu / Co |

|---|---|

| Tube setting | From 300 W to 600 W options in 30 kV or 40 kV setting |

| Tube housing | Patented design with Corrosion-resistant incident smart beam path technology (CRISP)

CRISP technology prevents corrosion in the incident beam path caused by X-ray induced ionized air. Patent no. US 8437451 B2 |

| Base configuration | Vertical goniometer, coupled and decoupled θ-θ, samples always horizontal |

|---|---|

| Geometry | Bragg-Brentano, Transmission, Grazing Incidence |

| Radius | 145 mm |

| Maximum 2θ range | -4° < 2θ ≤ 142° (with scanning detector and full active length) |

| Angle positioning | Direct optical position sensing (DOPS3) with lifetime positioning accuracy |

| Scan Speed | Max 2.17°/s |

| Resolution | < 0.04° 2θ on LaB6 (with 0.01 rad Soller slits) |

| 2θ linearity | < 0.04° 2θ |

| Smallest addressable increment | 0.001 ° |

| Spinning | Choice of spinner stages |

|---|---|

| Non-ambient | Heating stage option (BTS-500, BTS-150) |

| Exchange of stages | Alignment-free PreFIX exchange of stages |

| Special stages | On request (manual, MPSS, In-Situ) |

| Detector | Choose between the PIXcel1D, PIXcel3D and 1Der detectors |

| Dimensions | 690 x 770 x 786 mm |

|---|---|

| Dust protection | Closed system with external sample loading |

| External cooling water supply | Not needed |

| Compressed air supply | Not needed |

| Power Supply | 100 – 240 V, single phase |

| Computer | Internal instrument PC |

| Operation | Intuitive user interface with 10.4” touch screen |

| Interface | LAN, USB, HDMI |

Version number: 7

Version number: 8

Version number: 6

Version number: 7

Version number: 8

Version number: 8

Version number: 8

Version number: 2

Version number: 4

Version number: 3

Version number: 2

Version number: 4

Version number: 2

OmniTrust software update v1.7a

OmniAccess

OmniTrail

More information can be found in the Release and Installation Notes.

OmniAccess

OmniTrail

More information can be found in the Release and Installation Notes.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Fast high quality XRD, tailored for your requirements. Ready for automation and integration. The modern compact.