Analyses of a variety of sample types, including fused beads, pressed powders, metals, liquids and plastics, illustrate the performance of Omnian. This note demonstrates the flexibility of Omnian and illustrates numerous advanced features designed to enhance accuracy. All measurements were carried out on a Zetium WDXRF spectrometer.

In conventional XRF analysis multiple standard reference samples are used to make calibration lines for each of the elements to be analyzed. Preferably, these reference samples should have compositions similar to the unknown samples and when a large number of different sample types are to be analyzed, different calibrations need to be maintained for each type. This can be very time-consuming and expensive in terms of costly certified reference materials. Under such circumstances, standardless analysis with Omnian is a very valuable solution. With one measurement program, Omnian covers all elements from F to U and quantitative results can be obtained for a wide variety of sample types.

In conventional XRF analysis multiple standard reference samples are used to make calibration lines for each of the elements to be analyzed. Preferably, these reference samples should have compositions similar to the unknown samples and when a large number of different sample types are to be analyzed, different calibrations need to be maintained for each type. This can be very time-consuming and expensive in terms of costly certified reference materials. Moreover, in some cases there are no suitable reference materials available, or it may not be known in advance what the composition of the unknown samples might be. Under such circumstances, standardless analysis with Omnian is a very valuable solution. With one measurement program, Omnian covers all elements from F to U and quantitative results can be obtained for a wide variety of sample types.

Omnian can be used in combination with additional dedicated measurement programs. This gives the full flexibility to optimize the program, e.g. for extra speed or extra accuracy and precision. The standard measurement program takes approximately 20 minutes and contains ten scans to cover the elements from F to U. The program is easily extended with extra scans to cover additional elements, for instance boron, carbon and nitrogen.

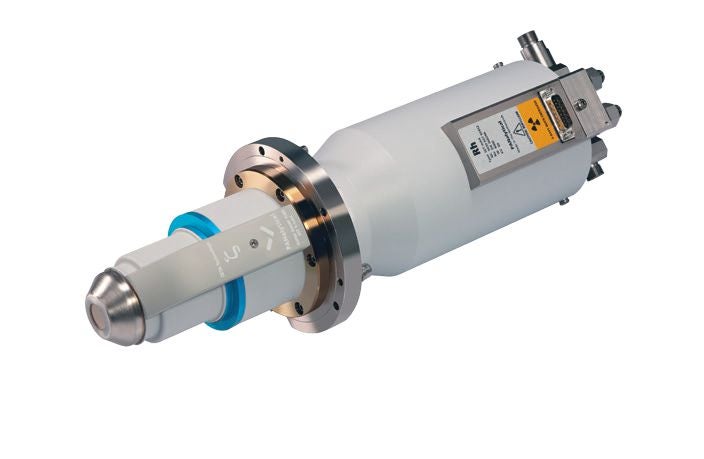

A FastScan program covering the same range of elements only takes about 2 minutes. To obtain a better accuracy and precision for minor and trace elements, goniometer channel measurements can be added for these elements. Analyses of a variety of sample types, including fused beads, pressed powders, metals, liquids and plastics, illustrate the performance of Omnian. This note demonstrates the flexibility of Omnian and illustrates numerous advanced features designed to enhance accuracy. All measurements were carried out on a Zetium WDXRF spectrometer.

Omnian is available for the full range of Zetium sequential spectrometers, including the Zetium with 1 kW operating power.Omnian is available for an array of spectrometers including sequential WDXRF (Zetium, MagiX, Axios mAX) and benchtop EDXRF spectrometers. Omnian offers standardless quantitative analysis of unknown solid, liquid and powder samples Designed for ease of use, Omnian is supplied with a default analytical recipe and a specifically manufactured set of reference samples for the initial setup. Omnian utilizes full fundamental parameter calculations and numerous advanced algorithms designed to achieve the superior standardless accuracy. Program features include:

• Fundamental parameter (FP) calculations

• Flexible sample description

• Adaptive sample characterization (ASC)

• Finite thickness (FT) corrections

• Fluorescence volume geometry (FVG) corrections

• Dark matrix (DM) characterization

• Line-overlap corrections

• Wavelength scan/EDXRF spectrum and channel measurements (WDXRF only)

All sample types and forms can be measured, including solids, pressed or loose powders, fused beads and liquids. Omnian includes provisions for detailed sample and sample preparation information. These details are used to deliver the best accuracy possible.

A glass standard (NIST 1831) was measured using both default and fast scan methods. Table 1 demonstrates excellent agreement between measured and certified values for both major and minor elements. Better accuracy for the minor elements was achieved using the default scan method.

Table 1: Certified values versus default and fast scan measured concentrations with Omnian for glass standard NIST 1831 (< LLD = below detection limit)

| Compound | Default scan 20 min. | First scan 1 min. (%) | Certified (%) |

| Na2O | 13.34 | 13.33 | 13.32 |

| MgO | 3.59 | 3.49 | 3.51 |

| AI2O3 | 1.23 | 1.30 | 1.21 |

| SiO2 | 73.26 | 73.58 | 73.08 |

| SO3 | 0.25 | 0.22 | 0.25 |

| K2O | 0.27 | 0.29 | 0.33 |

| CaO | 7.9 | 7.7 | 8.2 |

| TiO2 | 0.019 | <LLD | 0.019 |

| Fe2O3 | 0.085 | 0.076 | 0.087 |

Two standards, soil (NIST 2710) and blast furnace slag (SL-1, NRC) were prepared as fused beads (1 g sample and 10 g flux) and measured using default conditions. Tables 2 and 3 illustrate excellent agreement between measured results and certified values from low to high concentrations.

Table 2. Certified values versus Omnian-measured concentrations for soil standard NIST 2710. The soil was prepared as a fused bead and loss on ignition (LOI) was used as balance compound.

| Compound | Unit | Measured | Certified |

| Na2O | % | 1.62 | 1.54 |

| MgO | % | 1.42 | 1.41 |

| AI2O3 | % | 12.35 | 12.16 |

| SiO2 | % | 61.36 | 61.97 |

| P205 | % | 0.26 | 0.24 |

| SO3 | % | 0.27 | 0.60 |

| K2O | % | 2.27 | 2.54 |

| CaO | % | 1.71 | 1.75 |

| TiO2 | % | 0.46 | 0.47 |

| MnO | % | 1.34 | 1.30 |

| Fe2O3 | % | 4.84 | 4.83 |

| Cu | mg/kg | 2660 | 2645 |

| Zn | mg/kg | 6870 | 6929 |

| As | mg/kg | 561 | 579 |

| Rb | mg/kg | 142 | 135 |

| Sr | mg/kg | 334 | 359 |

| Pb | mg/kg | 5914 | 5848 |

Table 3. Certified values versus Omnian - measured concentrations for blast furnace slag standard (SL-1, NRC). The slag was prepared as a fused bead and LOI was used as a balance compound.

| Compound | Measured (%) | Certified (%) |

| Na2O | 0.43 | 0.39 |

| MgO | 12.21 | 12.27 |

| AI2O3 | 9.63 | 9.63 |

| SiO2 | 35.76 | 35.73 |

| S | 1.05 | 1.26 |

| K2O | 0.48 | 0.51 |

| CaO | 36.79 | 37.48 |

| TiO2 | 0.35 | 0.38 |

| MnO | 0.88 | 0.86 |

| FeO | 0.91 | 0.92 |

Element-specific goniometer channels can be added to the Omnian measurement program (for WDXRF systems only). Longer counting times can be specified on the peak and background positions giving higher precision for those elements. This results in better accuracy and precision for low-concentration elements.

The combination of the high-speed data processing counting electronics and the quick, reproducible movements of the Zetium DOPS (direct optical position sensing) goniometer, makes it possible to obtain a full standardless analysis within 2 minutes. The graphic below is an example of a spectrum obtained in FastScan mode.

A low alloy steel standard (BAS SS 405) was measured using the Omnian default conditions. Table 4 illustrates the reliability of Omnian for the analyses of metal samples.

Table 4. Certified values versus Omnian-measured concentrations for low alloy steel (BAS SS 405) standard. Fe was chosen as a balance calculated element.

| Element | Measured (%) | Certified (%) |

| Si | 1.25 | 1.38 |

| P | 0.014 | 0.017 |

| S | 0.069 | 0.060 |

| V | 0.34 | 0.32 |

| Cr | 0.23 | 0.21 |

| Mn | 1.35 | 1.28 |

| Ni | 0.12 | 0.12 |

| Cu | 0.020 | 0.015 |

| Mo | 0.015 | 0.017 |

Omnian is capable of measuring loose powder samples. A poplar leaf standard (GSV3) was prepared as a loose powder (5 g in a P2 cup assembled with 6 µm polypropylene X-ray film support) and was measured using default conditions. The results in Table 5 illustrate good agreement between measured and certified concentrations for a wide range of elements.

Table 5. Certified values versus Omnian- measured concentrations for poplar leaves standard (GSV3). Bracketed values are not certified and CH2O was used as a balance compound (a proxy for cellulose).

| Element | Unit | Measured | Certified |

| Na | % | 182 | 200 |

| Mg | % | 0.81 | 0.65 |

| AI | % | 0.115 | 0.104 |

| Si | % | 0.75 | 0.71 |

| P | % | 0.188 | 0.168 |

| S | % | 0.38 | 0.35 |

| CI | % | 0.25 | (0.23) |

| K | % | 1.39 | 1.38 |

| Ca | % | 1.84 | 1.81 |

| Ti | mg/kg | 30 | 20 |

| Mn | mg/kg | 49 | 45 |

| Fe | mg/kg | 276 | 274 |

| Cu | mg/kg | 17.0 | 9.3 |

| Zn | mg/kg | 39 | 37 |

| Br | mg/kg | 8.0 | 7.2 |

| Rb | mg/kg | 6.0 | 7.6 |

| Sr | mg/kg | 140 | 154 |

The standardless analysis of plastic materials presents additional analytical complications that are related to light matrices and sample thickness and often result in poor accuracy when using traditional standardless analysis approaches. Omnian includes smart features (FT and FVG, see sidebar) which automatically correct for these complications and result in improved accuracy. A polyethylene reference sample (BCR 681k) was measured with Omnian, Table 6.

Table 6. Certified values versus Omnian-measured concentrations for polyethylene disk standard (BCR 681K – 2 mm thick).

| Element | Measured (mg/kg) | Certified (mg/kg) |

| Cr | 102 | 100 |

| Br | 790 | 770 |

| Cd | 148 | 137 |

| Hg | 20.0 | 23.7 |

| Pb | 108 | 98 |

Typically pressed pellet samples are more challenging than metals, glasses or fused beads. This is because particle size variations and mineralogical effects can significantly impair their analysis. Fortunately, Omnian contains an adaptive sample characterization (ASC) strategy to provide reliable results, Table 7.

Table 7. Certified values versus Omnian-measured concentrations for limestone pressed powder standard (GBS 07215). CO2 was determined using balance (bal.) calculations.

| Compound | Measured (%) | Certified (%) |

| CO2 | 42.57 (bal.) | 42.20 |

| MgO | 2.29 | 2.37 |

| AI2O3 | 0.77 | 0.83 |

| SiO2 | 1.80 | 1.84 |

| SO3 | 0.755 | 0.710 |

| K2O | 0.168 | 0.158 |

| CaO | 51.2 | 51.3 |

| Fe2O3 | 0.466 | 0.518 |

A soil sample (NIST 2710) was prepared as a fused bead and measured ten times. The results are presented in Table 8. The average measured concentrations for all elements were very close to the certified values and standard deviations of the repeated measurements were low. The results indicate the excellent stability and reproducibility of the Zetium and Omnian combination

Table 8. Repeatability results for soil fused bead sample NIST 2710, measured ten times. LOI was used as the balance compound.

| Compound | Unit | Certified | Average of 10 | RMS |

| Na2O | % | 1.54 | 1.64 | 0.04 |

| MgO | % | 1.41 | 1.43 | 0.02 |

| AI2O3 | % | 12.16 | 12.46 | 0.07 |

| SiO2 | % | 61.97 | 60.95 | 0.29 |

| P2OS | % | 0.24 | 0.27 | 0.01 |

| SO3 | % | 0.60 | 0.27 | 0.01 |

| K2O | % | 2.54 | 2.29 | 0.03 |

| CaO | % | 1.75 | 1.74 | 0.02 |

| TiO2 | % | 0.47 | 0.45 | 0.01 |

| MnO | % | 1.30 | 1.34 | 0.02 |

| Fe2O3 | % | 4.83 | 4.87 | 0.06 |

| Cu | mg/kg | 2950 | 2645 | 33 |

| Zn | mg/kg | 6952 | 6929 | 62 |

| As | mg/kg | 626 | 579 | 68 |

| Rb | mg/kg | 120 | 135 | 9 |

| Sr | mg/kg | 240 | 359 | 12 |

| Pb | mg/kg | 5532 | 5848 | 74 |

| Description | Basis | Optional | |

| Sample Handling | |||

| Types | Solid, fused beads, filters, pressed/loose powders and liquids X-Y changer with priority position for 1 sample | ● | |

| Sample changer | (detected | ● | |

| X-ray tube SST-RmaX | |||

| Anode | Rh, ZETA technology | ● | Cr |

| Window | Ultra-high transmission, 75 µm | ● | 50 micron |

| Window coating | CHI-BLUE coating for corrosion resistance | ● | |

| Zetium | 20 - 60 kV, 16 - 50 mA | 1 kW | 2.4, 3 amd 4 kW |

| Goniometer | |||

| Type | θ/2θ decoupled with Direct Optical Position Sensing (DOPS) | ● | |

| Optical path | |||

| Channel masks | Single mask (fixed 27, 30 or 37 mm),

| ● | |

| Primary collimators | 3 max.: 100, 150, 300, 550, 700 and 4000 µm | 2 of choice | Additional of choice |

| Primary beamfilters | 4 max.: One may be used as beam stop | 4 of choice | |

| Crystals | 8 max.: LiF420, LiF220, LiF200, Ge111 (flat/curved), PE002 (flat), InSb (flat/curved),TlAP coated, PX1, PX8, PX10 | PX1, LiF200, PE002, Ge111, LiF220 | Additional of choice

Ge111 curved and PE002 curved |

| Dust removal device | Prevention of dust entering the optical path | ● | |

| Detectors | Flow, scintillation

Duplex counter Hiper Scint | ● | |

| Fixed channels | HiPer channel (from B to Mg) | ● | |

| Beam path | Vacuum: <10 Pa; | He (N2)

| |

| ED channel | SDD detector | ● | |

| Small Spot Mapping | Elemental mapping combined with the SDD detector | ● | |

| Application modules |

| ||

| Software | SuperQ, including Statistic Process Control module (SPC) | ● | |

| Omnian, Enhanced Data Security, Stratos, Type Standardization | Additional of choice | ||

| Automation interfacing

| Software and hardware adaptation for automation integration | ● | |

| Safety standards

| Compliant to global industry safety regulations | ● | |