Eagon 2 Pre-installation Manual

Version number: 6

Looking for more information?

To request a quote, more information or download a brochure select an option below.

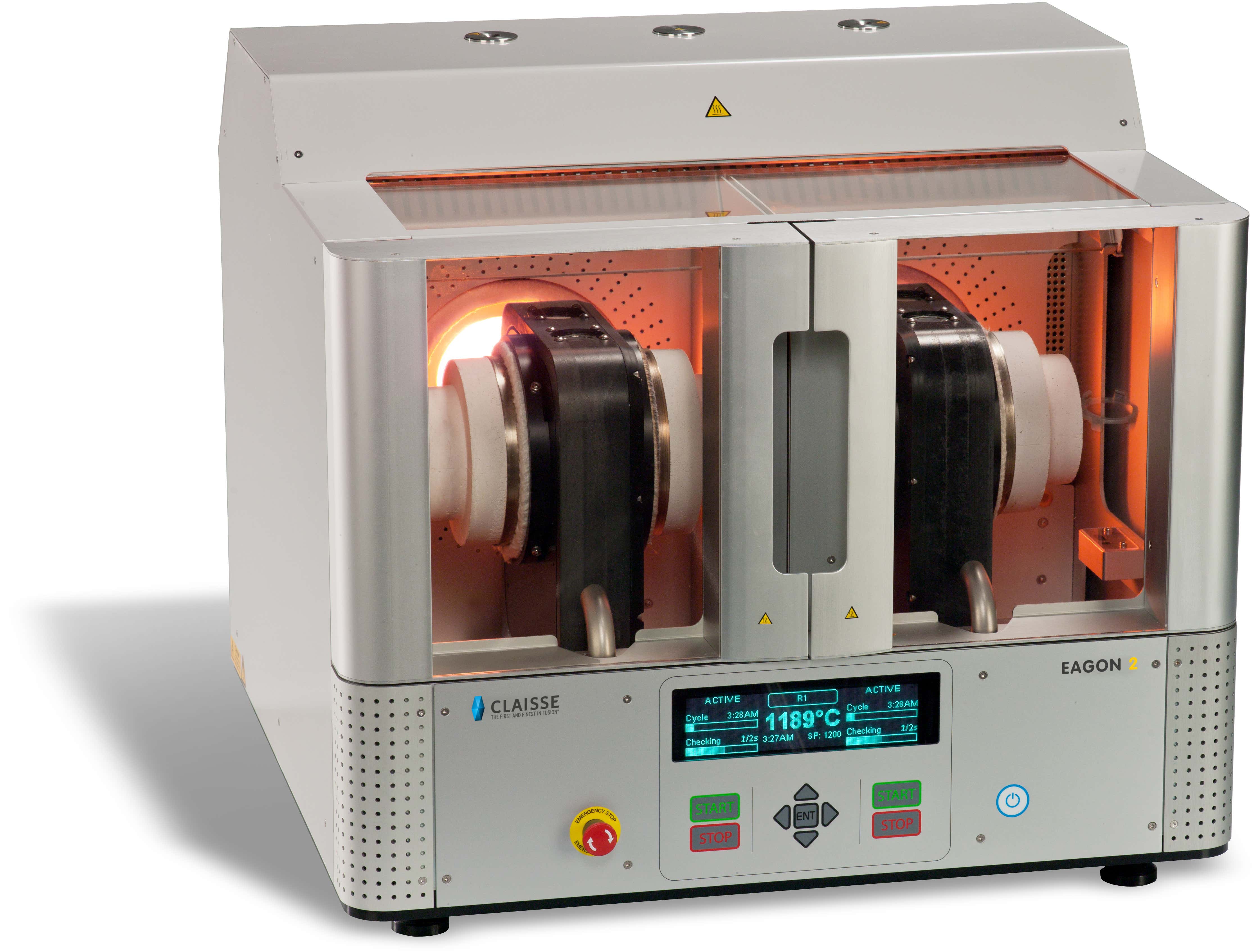

Eagon 2, a Claisse technology, is a fully automatic fusion instrument. It can process two samples simultaneously and is used to prepare glass disks for XRF analysis.

Eagon 2 leads to high performance and productivity in the laboratory since its two fusion positions can work independently (synchronous or asynchronous mode) and because it guarantees reproducibility as well as optimized fusion conditions.

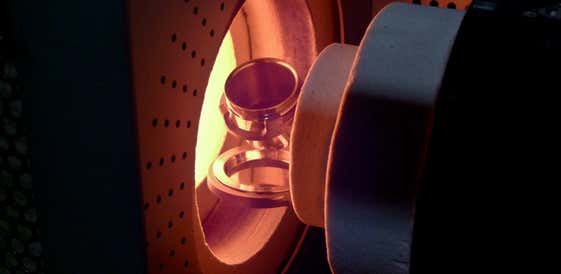

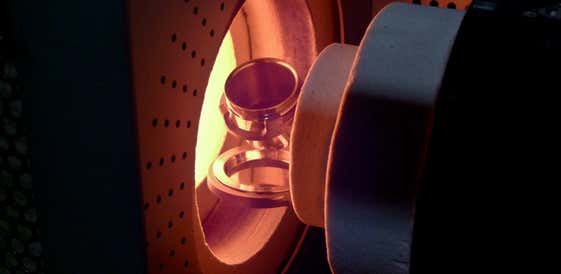

The molds and crucible holders are made of superior quality ceramic to ensure the lowest contamination.

The interlocked doors eliminate contact with hot materials and surfaces.

This enables enhanced security and a total cold-to-cold operation.

The Claisse Eagon 2 instrument has a one-touch operation feature and a wide range of predefined fusion methods that make it really easy to operate in the laboratory.

It has distinguishing features that allow a quick return on investment (ROI) such as casting dish sensors that prevent damage related to pouring without the molds in place.

| Operating temperature (°C) | 300 - 1200 |

|---|---|

| Sample heating | Resistance-based heating system |

| Power | 220-230 V 32 A 50-60 Hz |

| Dimensions (W, D, H) | 64.5 cm (25.4 in.) x 68.5 cm (27.0 in.) x 56.5 cm (22.2 in.) |

| Weight | 78 kg (172 lb.) |

| Certification | Certified CE and machinery directive 98/37/EC compliant |

| Safety | Outer doors are interlocked during fusion cycle to enhance safety

Maximum external temperature of 70ºC Casting dish sensors ensure safe and reliable operation |

Version number: 6

Version number: 8

Version number: 8

Please contact support for the latest software version.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Adding value to your processes

Eagon 2, a Claisse technology, is a fully automatic fusion instrument. It can process two samples simultaneously and is used to prepare glass disks for XRF analysis.

Eagon 2 leads to high performance and productivity in the laboratory since its two fusion positions can work independently (synchronous or asynchronous mode) and because it guarantees reproducibility as well as optimized fusion conditions.

The molds and crucible holders are made of superior quality ceramic to ensure the lowest contamination.

The interlocked doors eliminate contact with hot materials and surfaces.

This enables enhanced security and a total cold-to-cold operation.

The Claisse Eagon 2 instrument has a one-touch operation feature and a wide range of predefined fusion methods that make it really easy to operate in the laboratory.

It has distinguishing features that allow a quick return on investment (ROI) such as casting dish sensors that prevent damage related to pouring without the molds in place.

| Operating temperature (°C) | 300 - 1200 |

|---|---|

| Sample heating | Resistance-based heating system |

| Power | 220-230 V 32 A 50-60 Hz |

| Dimensions (W, D, H) | 64.5 cm (25.4 in.) x 68.5 cm (27.0 in.) x 56.5 cm (22.2 in.) |

| Weight | 78 kg (172 lb.) |

| Certification | Certified CE and machinery directive 98/37/EC compliant |

| Safety | Outer doors are interlocked during fusion cycle to enhance safety

Maximum external temperature of 70ºC Casting dish sensors ensure safe and reliable operation |

Version number: 6

Version number: 8

Version number: 8

Please contact support for the latest software version.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Adding value to your processes

Synchronous and asynchronous fusion with predefined methods for improving productivity in any laboratory.