Overview

Analytical versatility with superior throughput

Surface area and porosity are important physical properties that influence the quality and utility of many materials and products. It is critical that these characteristics be accurately determined and controlled.

Similarly, knowledge of surface area and especially porosity are important properties in understanding the formation, structure, and potential application of many natural materials.

Features

The Micromeritics ASAP 2460 surface area and porosimetry analyzer incorporates a unique expandable system designed for high performance and high sample throughput. The base ASAP 2460 is a two-port master control unit. For more throughput, additional two-port auxiliary units can be connected to the master unit, expanding the system to either a four-port or six-port analyzer.

- Fully automated modular design: ideal for walk-up sample screening with scalable configurations

- Flexible throughput options: choose from 2, 4, or 6 independent analysis stations to match your lab’s workload

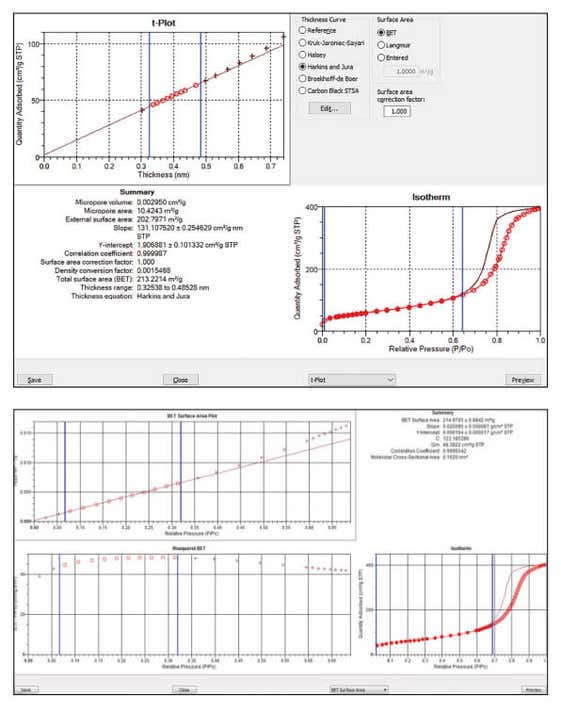

- Rapid BET surface area analysis: complete measurements in as little as 30 minutes

- Customizable dosing control: select maximum volume increments or dosing across specific pressure ranges

- Adjustable analysis temperature: enter or automatically calculate temperatures for accurate results

- Equilibration timing flexibility: specify equilibration durations for different isotherm regions to optimize data quality

- Low surface area & micropore capabilities: expand analysis range with specialized options

- Advanced MicroActive software: features advanced NLDFT modeling for detailed pore structure analysis

- Precision engineering: ensures consistent accuracy, repeatability, and reproducibility across all ports and control units

Applications

Surface area and porosity play major roles in the purification, processing, blending, tableting, and packaging of pharmaceutical products as well as their useful shelf life, dissolution rate, and bioavailability.

Surface area and porosity affect the curing and bonding of greenware and influence strength, texture, appearance, and density of finished goods. The surface area of glazes and glass frits affects shrinkage, crazing, and crawling.

Knowledge of surface area, total pore volume, and pore size distribution is important for quality control of industrial adsorbents and in the development of separation processes. Surface area and porosity characteristics affect the selectivity of an adsorbent.

Surface area and porosity must be optimized within narrow ranges to accomplish gasoline vapor recovery in automobiles, solvent recovery in painting operations, or pollution controls in waste-water management.

The wear lifetime, traction, and performance of tires are related to the surface area of carbon blacks used in their production.

The active surface area and pore structure of catalysts influence production rates. Limiting the pore size allows only molecules of desired sizes to enter and exit, creating a selective catalyst that will produce primarily the desired product.

The surface area of a pigment or filler influences the gloss, texture, color, color saturation, brightness, solids content, and film adhesion properties. The porosity of a print media coating is important in offset printing where it affects blistering, ink receptivity, and ink holdout.

The burn rate of propellants is a function of surface area. Too high a rate can be dangerous; too low a rate can cause malfunction and inaccuracy.

Controlling the porosity of artificial bone allows it to imitate real bone that the body will accept and allow tissue to be grown around it.

By selecting high surface area material with carefully designed pore networks, manufacturers of super-capacitors can minimize the use of costly raw materials while providing more exposed surface area for storage of charge.

Surface area is often used by cosmetic manufacturers as a predictor of particle size when agglomeration tendencies of the fine powders make analysis with a particle-sizing instrument difficult.

Surface area and porosity of heat shields and insulating materials affect weight and function.

Porosity is important in groundwater hydrology and petroleum exploration because it relates to the quantity of fluid that a structure can contain as well as how much effort will be required to extract it.

Nanotube surface area and microporosity are used to predict the capacity of a material to store hydrogen.

Fuel cell electrodes require high surface area with controlled porosity to produce optimum power density.