Overview

The Micromeritics ChemiSorb HTP is a fully automated, high-throughput chemisorption analyzer for characterizing catalysts, metal-supported nanoparticles, and chemically active materials used in sensor applications. Six independent stations running parallel analyses reduce operator intervention and increase lab productivity.

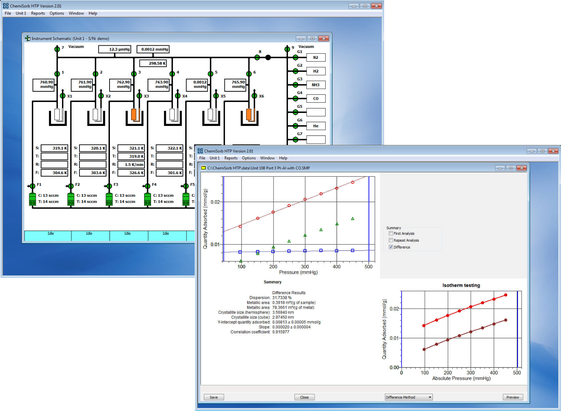

The ChemiSorb HTP is a static manometric chemisorption analyzer. Generally, two adsorption ‘isotherms’ (quantity of gas adsorbed as a function of pressure at constant temperature) are collected at sub-atmospheric pressures: the first representing total adsorption, the second representing reversible adsorption, and the difference between the two representing the irreversible adsorption (i.e. ‘chemisorption’).

This technique provides information on the quantity of adsorption sites, from which subsequent calculations may be done for the percent metal dispersion, active metal surface area, size of active particles, and surface acidity of catalyst materials.

Static chemisorption provides the highest level of detailed surface characterization, providing total chemisorption, irreversible (strong) chemisorption, and reversible (weak) chemisorption over the widest range of catalyst chemistries.

Features

-

Provides a stable isothermal process zone to eliminate condensation of vapors and provide long-term process stability

-

High vacuum, high-resolution, low-pressure transducers provide precise and reproducible results

-

Up to twelve gases can be connected to the ChemiSorb HTP, covering many activation/analysis possibilities

-

Catalysts activation procedures are made in-situ, avoiding the risk of sample contamination prior to the experiment

-

Independent sample ports maximize versatility; each reactor has its own furnace, working from ambient up to 700 °C

-

Fully automated operation – including activation, motor-driven furnaces, and programmed analysis sequences – guarantees reproducibility and reduces operator intervention

Why ChemiSorb HTP?

Six parallel analysis stations

ChemiSorb HTP features six independent analysis stations with dedicated pressure sensors, mass flow controllers, and temperature control for each analysis station.

Multiple analyses can be performed simultaneously or in parallel on one instrument. This saves time and lab space for busy catalyst operations. Samples may be added or removed from each station without disturbing the treatment of other samples undergoing preparation or analysis.

The instrument features long unattended analysis times and a high-throughput mode that allows the user to start multiple parallel analyses.

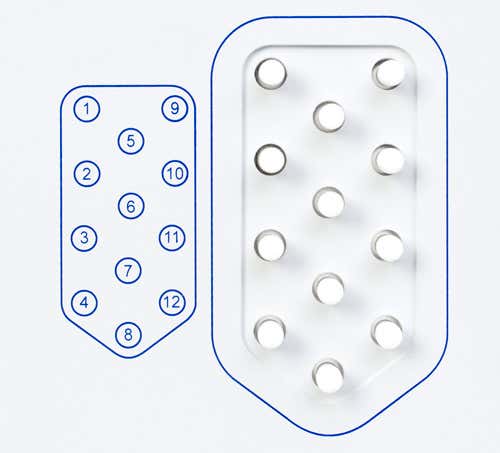

Twelve gas inlets

Twelve gas inlet ports provide flexibility to study chemisorption with a variety of probe molecules that can be used in automatically sequenced procedures without operator intervention.

Probe many surface chemistries of interest without moving gas bottles or connections, so you can perform the measurements you need without hassle.

In-situ preparation with precision temperature control

Degas/sample preparation is performed at the analysis port immediately prior to analysis. The guarantees complete preparation without risk of exposure to atmosphere.

Each port is equipped with a dedicated furnace for independent control of sample temperature and ramping from 10 ºC above ambient to 700 ºC. The temperature is recorded with each equilibrium pressure to provide the highest quality isotherms.

Software

The Micromeritics ChemiSorb HTP includes a full suite of software for reporting important parameters used to describe active sites, including:

- Percent of metal dispersion

- Active metal surface area

- Crystallite size of the active particles

- Surface acidity of catalyst materials

Advanced software features are included as standard:

- Real-time, intuitive instrument status view and control

- High-throughput mode for simple execution of a batch of similar measurements

- Interactive click-and-drag data processing

- Customized, automated report definition