Overview

Designed for applications that require smaller sample sizes, the Hydro MV is especially valuable when the supply of test material is limited or when dispersant usage must be minimized.

- 120 ml dispersant volume.

- 40 W in-line sonication probe, for rapid agglomerate dispersion.

- Powerful centrifugal pump system ensures bias-free sampling.

- Automated dispersant supply.

- Chemically compatible with a wide choice of organic and inorganic dispersants.

- Full software control of all measurement functions, including dispersant supply, sample dispersion and cleaning.

- Integral sample tank light.

How it works

Dispersing a sample within a liquid involves wetting and separating each individual particle. The aim is to produce a stable, completely dispersed suspension for measurement.

In order to promote wetting, it is vital to select an appropriate dispersant. Water is the one most commonly used and, when suitable, offers many benefits in terms of cost of measurement and sample disposal. With certain liquid dispersion applications, such as those involving water soluble particles, aqueous measurement is not appropriate. Here, organic dispersants are often required and it can become important to minimize dispersant volumes within the constraint of producing a stable, representative suspension for measurement.

The application of sonication promotes the wetting process, by disrupting the structure of any agglomerates. Stabilizers may also be added to the dispersant to prevent re-agglomeration.

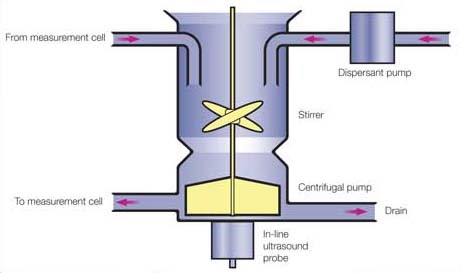

The Hydro MV is designed for medium volume wet dispersion and is suitable for a very broad range of sample types. In-line sonication promotes the dispersion process while a powerful centrifugal pump prevents sedimentation, ensuring that the entire sample is measured in a bias-free way. Automated dispersant delivery of both organic and inorganic dispersants allows optimisation of the dispersion process and accelerates analysis.

Wet Dispersion unit schematic, showing the sample tank, stirrer, centrifugal pump and in-line sonication system.

Specification

| Pump speed range | 0-3500 rpm †† |

|---|---|

| Pump speed accuracy | +/- 50 rpm |

| Pump speed resolution | +/- 10 rpm |

| Maximum flow rate | 2.0 l/min. †† |

| Sonication power & frequency | 40W max, 40kHz (nominal) †† |

| Maximum volume | 120ml |

| Materials in contact with the dispersant, additives and sample | 316 stainless Borosilicate Glass Tygon® R-3603. ††† Viton (cell seal only - perfluoroelastomer upgrade available) PTFE PEEK FEP Titanium Nitride Aluminum (tubing connectors only) Acrylic (splash guard only) |

| Maximum particle size | 1500 µm † |

| Minimum time between measurements | Less than 60 seconds † |

| Dimensions (W, D, H) | 180mm x 280mm x 300mm |

| Weight | 5kg |

| † | Sample dependent |

| †† | Dispersant dependent |

| ††† | Other tubing grades available on request |