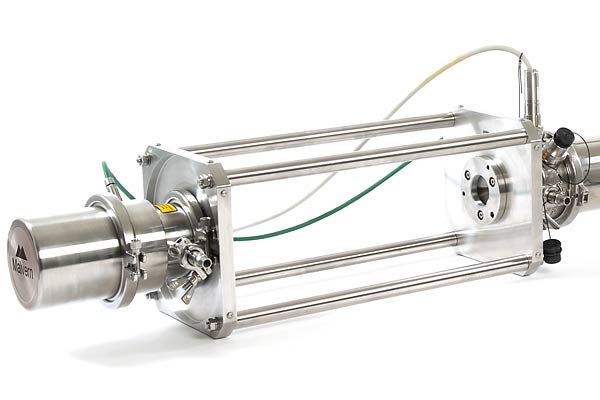

Insitec Spray customized configuration

Fully customized, reliable, robust particle sizing for sprays and aerosols.

A variable path length particle sizing sensor that offers maximum flexibility for spray and aerosol applications, delivering reliable, continuous monitoring 24/7. Suitable for droplets or particles from 0.1 to 2500µm with an intrinsically safe option for zoned hazardous environments.