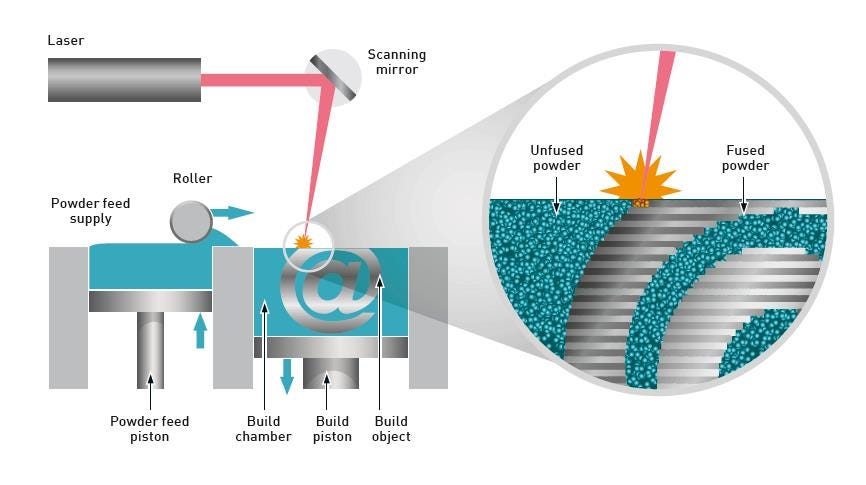

Powder bed fusion is an additive manufacturing (AM) process where an energy source, such as a laser or electron beam, is used to fuse particulate materials such as metals, ceramic or polymers together to form a three-dimensional object. Common techniques include selective laser sintering, selective laser melting, and electron beam melting.

In powder bed processes, particularly for metals, powder cost can account for up to a third of the total production cost of the final additive manufacturing component. Commercial viability therefore relies on a robust supply chain and effective metal powder recycling strategies. Moreover, the metal powder’s chemical and physical properties directly affect the build process and final component quality. To maintain process robustness and consistency, these properties must be controlled and optimized.

To achieve this, powder properties must be characterized at various stages in the supply chain – from new alloy or polymer development through to powder recycling. Laser diffraction, automated image analysis, X-ray fluorescence, and X-ray diffraction are four commonly used key analytical techniques for characterizing additive manufacturing powders.

At Malvern Panalytical, we offer expert analytical solutions for each of these techniques.

Please download our brochure to find out more.

Particle size

Particle size distribution is critical for powder-bed additive manufacturing processes, since it affects powder bed packing and flowability – which, in turn, affects build quality and final component properties.

To measure the particle size distribution of metal, ceramic, and polymer powders for additive manufacturing, laser diffraction is an established technique that is used by powder producers, component manufacturers, and machine manufacturers worldwide to qualify and optimize powder properties. Laser diffraction – either using our Mastersizer or online using Insitec. can provide a complete high-resolution particle size distribution in a laboratory setting.

Particle shape

Powder bed density and powder flowability are directly influenced by particle size and shape. Particle shape is therefore another important metric for powder bed additive manufacturing. Smooth regular-shaped particles are preferable because they can flow and pack more easily than those with a rough surface and irregular shape.

To enable additive manufacturers to achieve this regular shape, the Morphologi 4 automated imaging system can be used to classify and quantify the size and shape of metal, ceramic, and polymer powders. The Morphologi 4 does this by combining particle size measurements, such as length and width, with assessments of particle shape features, such as circularity and convexity (roughness).

Elemental composition

Elemental composition is particularly important for metal alloys, since small variations in the concentration of alloying elements can affect chemical and physical properties – including strength, hardness, fatigue life, and chemical resistance.

To detect these variations, contaminants or inclusions, and determine the elemental composition of these metal alloys and ceramics, X-ray fluorescence (XRF) systems such as our Zetium and Epsilon are routinely used. XRF also offers significant time and cost savings compared with alternative techniques.

Microstructure

Microstructural characteristics – such as phase composition, residual stress, grain size, and grain distribution (texture) – are critically important for metal additive manufacturing, since they can affect the chemical and mechanical properties of a manufactured component.

To analyze these microstructural characteristics and control the final component’s properties, benchtop X-ray diffraction (XRD) systems such as Aeris are routinely used to conduct phase analysis of metals. And for additional information on texture, grain size, and residual stress under a wide range of conditions, multi-purpose diffractometers like Empyrean can be used. XRD is also widely used to study the structure and crystallinity of polymers and ceramics.

Featured products