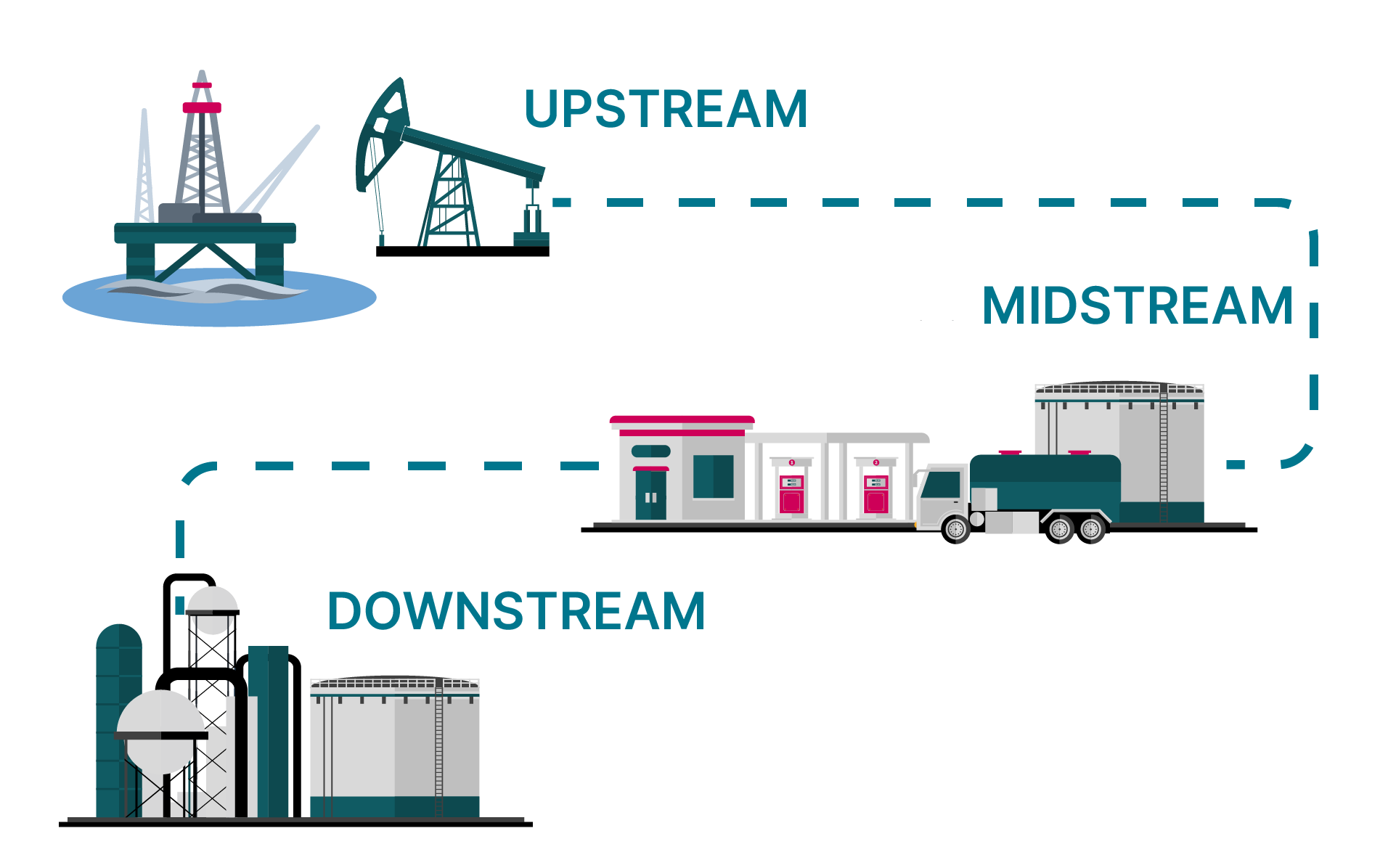

We help you operate profitable, innovative, durable assets – from oil rigs to petrochemicals plants

Across the oils and petrochemicals industry, the drive to improve environmental impact is growing. At the same time, given fluctuating oil prices, producers must continue to optimize their processes to achieve maximum efficiency and quality at minimal cost.

With challenges including hazardous chemicals, corrosion, weathering, and the shift toward automated, unmanned facilities, it can be tough to meet all these requirements. Our industry-leading solutions, quality control, compliance standards, and training make this easier. How? By helping you to secure high-quality fuels and polymers, identify impurities, reduce waste, and streamline your production processes.

Benefit from:

At Malvern Panalytical, we share the industry’s drive to operate more sustainably. To this end, alongside our own operational sustainability goals, we support our oils and petrochemicals customers to meet their environmental targets and address their production challenges.

Specifically, by offering a full spectrum of petrochemical and oil analysis solutions for all stages of the value chain, we enable these customers to optimize their processes for efficiency and ensure their materials are of the highest possible quality at the lowest possible environmental impact.

"If I had to rate my experience with Malvern Panalytical, I would easily give 9/10.

Their products are very efficient from an analytical point of view and the after-sales technical service is up to our expectations."

Marina Boccongelli - Total Belgium

Our petrochemical and oil analyzers help producers optimize their materials, processes, and products – whether it’s during exploration or quality control.