Cadmium tungstate (CdWO4) wafers are used as scintillation crystals to detect gamma rays. Waveguides can be fabricated in the crystals using laser cutting followed by gap filling with highly reflecting materials. These are then coupled to a large area CMOS sensor to form an X-ray imaging system. Under some conditions it was found that cracks could be seen to propagate from the cut edges and that the crack propagation was dependent upon the direction of laser cutting.

The 5-axis Eulerian cradles on the X’Pert³ MRD (XL) series diffractometers and the 5-axis sample stage on the Empyrean, together with their high-resolution 2theta and omega goniometers, are designed for precision, flexibility and ease of use. Furthermore the combined rocking curve and triple axis (TA) PreFIX optic enables the hands-free change-over from high-speed peak finding routines to high-precision peak position measurements. The orientation of a single crystal cadmium tungstate wafer was obtained, using a combination of rapid scans that could easily be formulated into batch routines.

Cadmium tungstate (CdWO4) wafers are used as scintillation crystals to detect gamma rays. Waveguides can be fabricated in the crystals using laser cutting followed by gap filling with highly reflecting materials. These are then coupled to a large area CMOS sensor to form an X-ray imaging system [1]. Under some conditions it was found that cracks could be seen to propagate from the cut edges and that the crack propagation was dependent upon the direction of laser cutting. The requirement here was to measure the orientation of the crystal in order to establish whether the observed crack behavior was related to the crystallographic orientation of the wafer.

The 5-axis Eulerian cradles on the X’Pert3 MRD (XL) series diffractometers and the 5-axis sample stage on the Empyrean, together with their high-resolution 2theta and omega goniometers, are designed for precision, flexibility and ease of use. Furthermore the combined rocking curve and triple axis (TA) PreFIX optic enables the hands-free change-over from high-speed peak finding routines to high-precision peak position measurements. The orientation of a single crystal cadmium tungstate wafer was obtained, using a combination of rapid scans that could easily be formulated into batch routines.

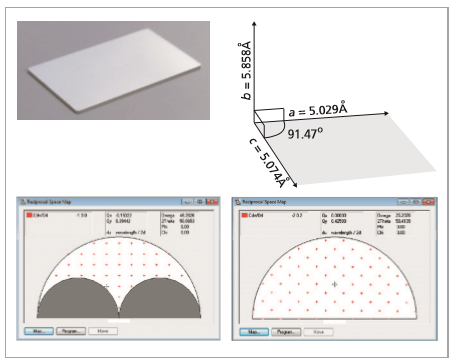

The rectangular wafer had approximate dimensions 25 mm x 16 mm x 0.4 mm and had been cut from a single crystal ingot of cadmium tungstate. It was expected to have a monoclinic structure with b (010) plane parallel to the wafer surface. The orientations of the side faces were not known. The ICDD powder diffraction file (00-014-0676) was used to provide information about the CdWO4 unit cell together with relative intensities for Bragg reflections. The Data Collector reciprocal space map tool was used to identify suitable reflections for investigation. Using a Bartels four-crystal incident beam monochromator, reflections were found by employing quick sequential phi and omega scans with an open detector, followed by peak position determination using high-resolution 2theta scans with a TA analyzer. Edge scattering experiments were also performed, using crossed slits to reduce the incident beam dimensions. Peak positions were also obtained using PIXcel1D static 2theta vs omega rapid

2-axis scans.

The 5-axis Eulerian cradles on the X’Pert3 MRD (XL) series diffractometers and the 5-axis sample stage on the Empyrean, together with their high-resolution 2theta and omega goniometers, are designed for precision, flexibility and ease of use. Furthermore the combined rocking curve and triple axis (TA) PreFIX optic enables the hands-free change-over from high-speed peak finding routines to high-precision peak position measurements. The orientation of a single crystal cadmium tungstate wafer was obtained, using a combination of rapid scans that could easily be formulated into batch routines.

Figure 1. Top left: A photograph of the cadmium tungstate sample. Top right: diagram of cadmium tungstate monoclinic unic cell. Below: Data Collector reciprocal space map tool for finding reflections from the wafer surface (left) and the edge faces (right) of the sample.

The table below summarizes the reflections that were captured and their angular coordinates. The sample was mounted so that the long edge corresponded to the phi = 0 position.Firstly the 010 and 020 symmetric reflections were found, verifying that the (010) planes were approximately parallel to the wafer surface. Measurement of the 130, 031, -130 and 03-1 asymmetric reflections and the -202 and 202 edge reflections provided a consistent picture of the wafer orientation which is illustrated in Figure 2 on a stereographic projection. The face on the long edge of the sample was 7.44° off (101) and the short edge of the sample was 8.67° off (-101). Figure 3 shows the result of the wafer offset determination in which it is shown that the top surface is true to (010) to within 0.2°.

Table 1. Results table showing the angular coordinates of captured reflections.

Figure 2. Schematic diagram showing the sample orientation overlaid on a stereographic projection illustrating the poles of the hkl planes whose reflections were captured

Figure 3. Offset was measured by a series of omega scans at different phi positions: The specular reflectivity data (orange) measure the sample surface orientation with respect to the sample stage and the data for the 020 reflection (blue) measure the crystal orientation with respect to the sample stage. The difference curve (gray data) gives the crystal orientation with respect to the sample surface.

Malvern Panalytical’s multipurpose diffractometers, equipped with a combination of high-resolution and rapid scanning optics can be used to identify the orientation of single crystal wafers. The combination of variable beam size, high-resolution monochromation and rapid scanning, ensures that relevant hkl peak positions can be found precisely and rapidly.