FT4 powder rheometer

Analyze powder flow properties and powder behaviour

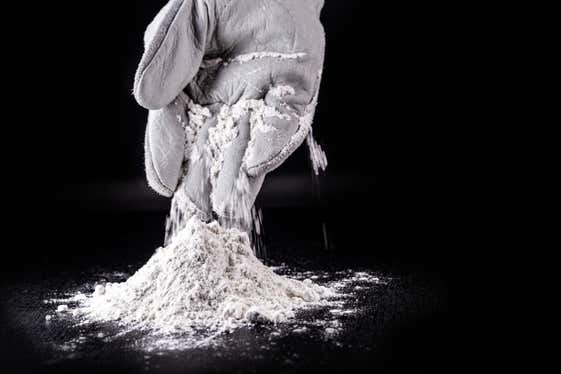

Powder flow characterization is essential for optimizing manufacturing processes across various industries. It involves analyzing how powdered materials behave under different conditions, which is crucial for ensuring product consistency and efficiency.

Several factors influence powder flow, including particle size, shape, density, surface area, moisture content, and electrostatic properties. These characteristics can significantly impact the handling and processing of powders in applications such as pharmaceuticals, additive manufacturing, and battery production.

To comprehensively assess powder flow, it's important to consider both dynamic and bulk properties:

By evaluating these parameters, manufacturers can predict and control powder behavior during processing, leading to improved product quality and reduced production issues.

Analyze powder flow properties and powder behaviour

Freeman Technology, developers of the industry-leading FT4 powder rheometer, became part of the Micromeritics family in 2018. In 2025, Micromeritics and Freeman joined Malvern Panalytical, bringing powder flow expertise into the wider materials characterization portfolio. Malvern Panalytical now offers state-of-the-art instruments designed to provide detailed insights into powder flow characteristics.

These tools help in identifying potential challenges in powder handling and processing, enabling proactive adjustments to manufacturing protocols.

For instance, our instruments can detect variations in powder properties that may lead to issues like poor flowability or inconsistent dosing, allowing for timely interventions.

Effective powder flow characterization is vital in various sectors:

Ensuring uniformity in tablet formulation and preventing issues like capping or lamination

Achieving consistent layer deposition and part integrity by controlling powder flow in processes like powder bed fusion

Optimizing electrode material packing and enhancing battery performance through precise powder handling

By integrating comprehensive powder flow analysis into quality control and R&D processes, companies can:

Malvern Panalytical's expertise in material characterization supports clients in achieving these goals through tailored solutions and expert guidance.