Overview

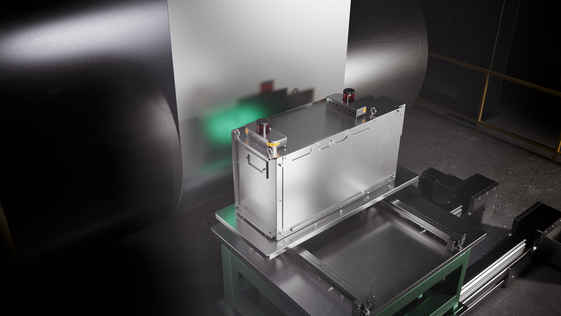

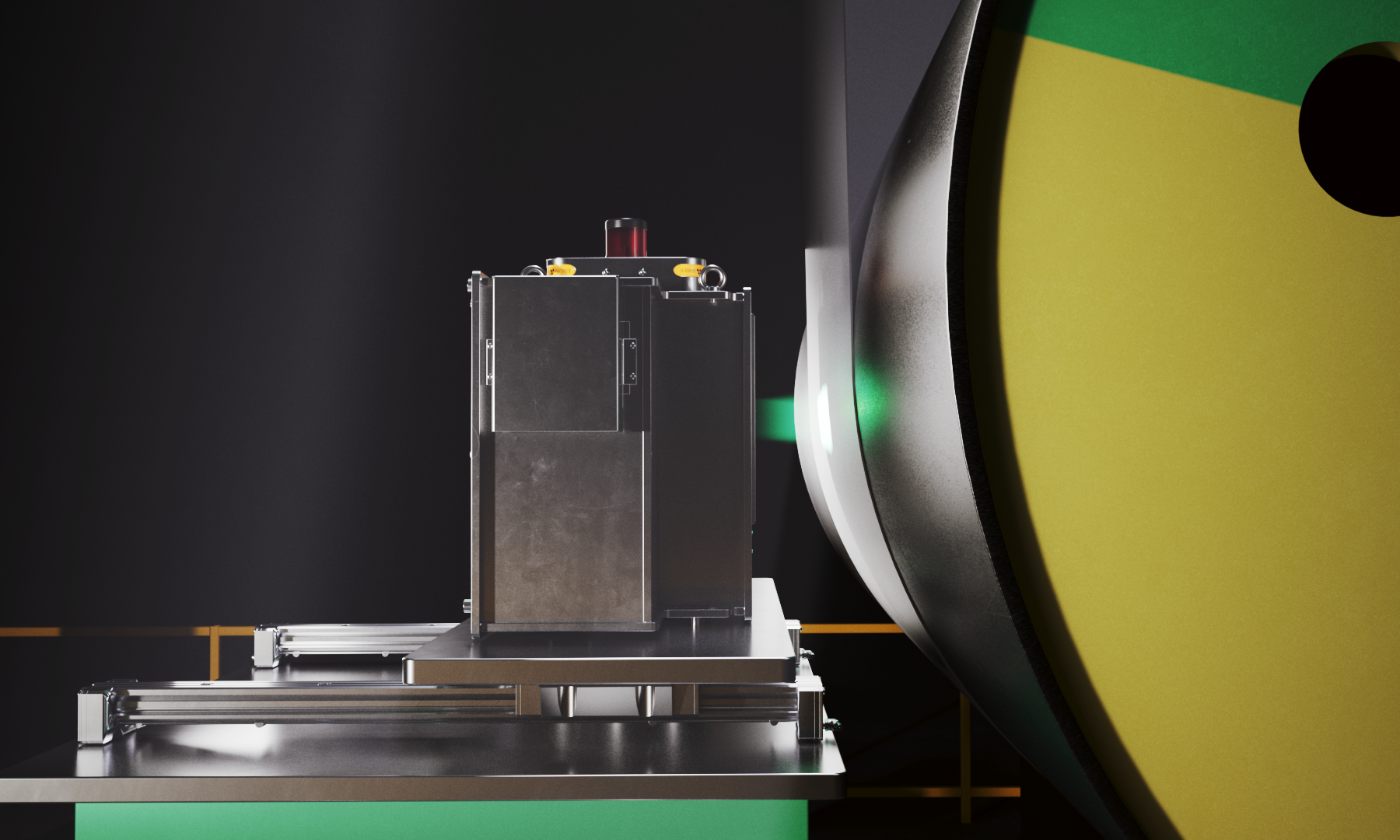

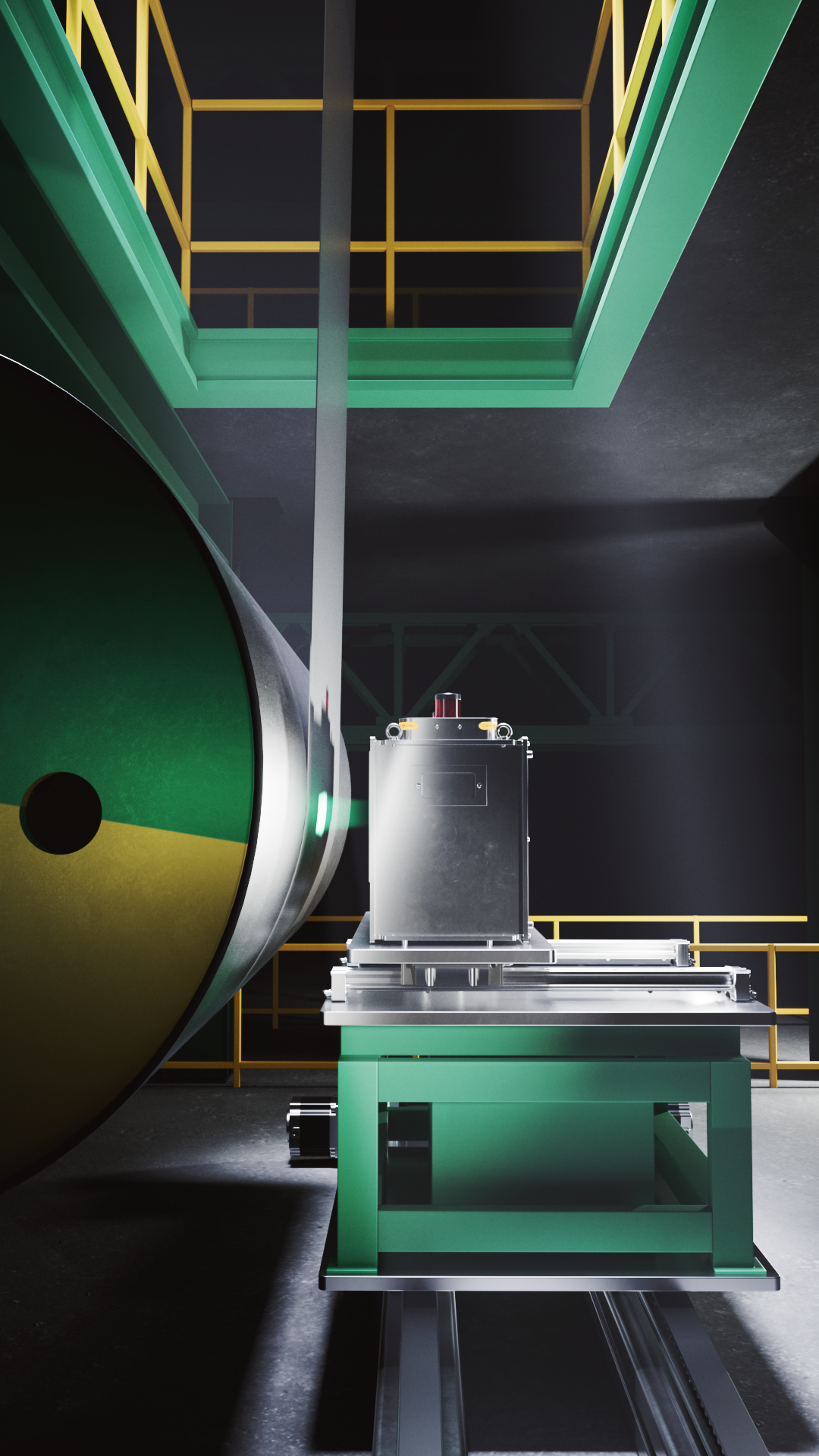

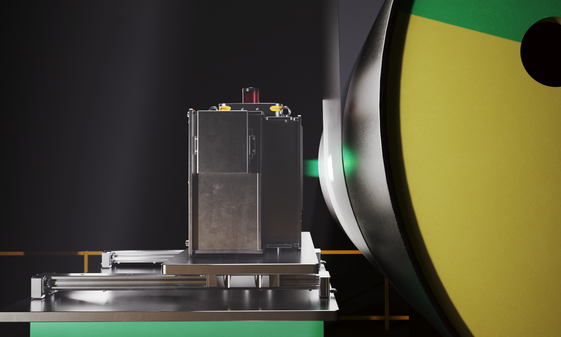

An on-line X-ray diffraction (XRD) instrument, created by experts from Malvern Panalytical in partnership with leading innovator Hyundai Steel.

With its first-class tube, detector, and software, the instrument allows steel production managers to benefit from continuous, real-time monitoring during steel galvannealing operations.

Quality measurements from our industry-first instrument mean you can cut down on errors, waste, and energy usage, as well as maximize precious uptime on your production line.

Features and benefits

-

Reduced process errors and waste: Monitoring your galvannealing process improves precision and reduces the need to re-melt your steel coil

-

Maximized uptime: On-line XRD provides on-line results in real time – enabling you to keep production running and allowing lab staff to focus on other tasks

-

Improved cost efficiency: Reduce your raw material and energy usage, maximize productivity by improving your uptime, and sell your steel for the highest possible price

-

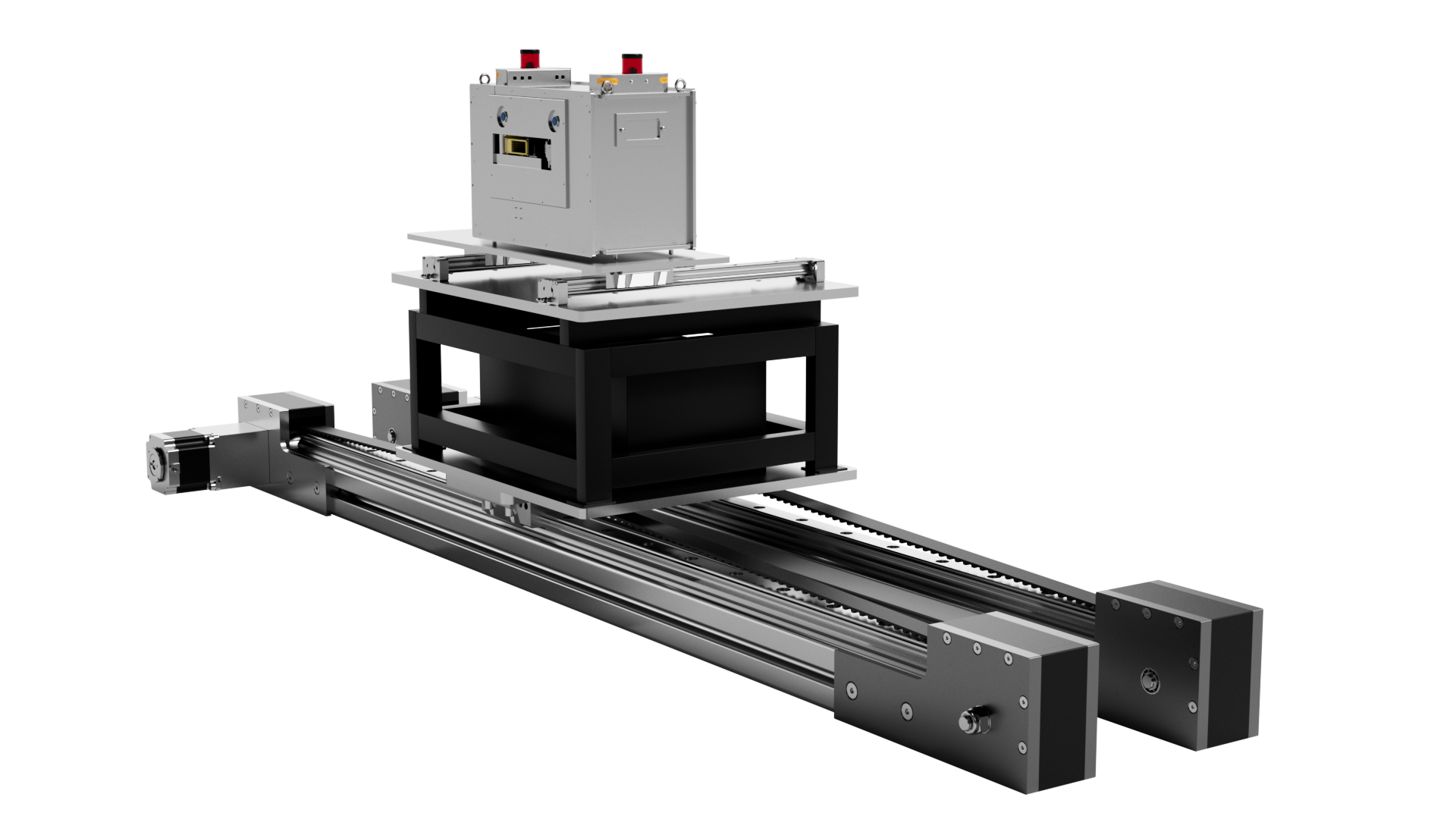

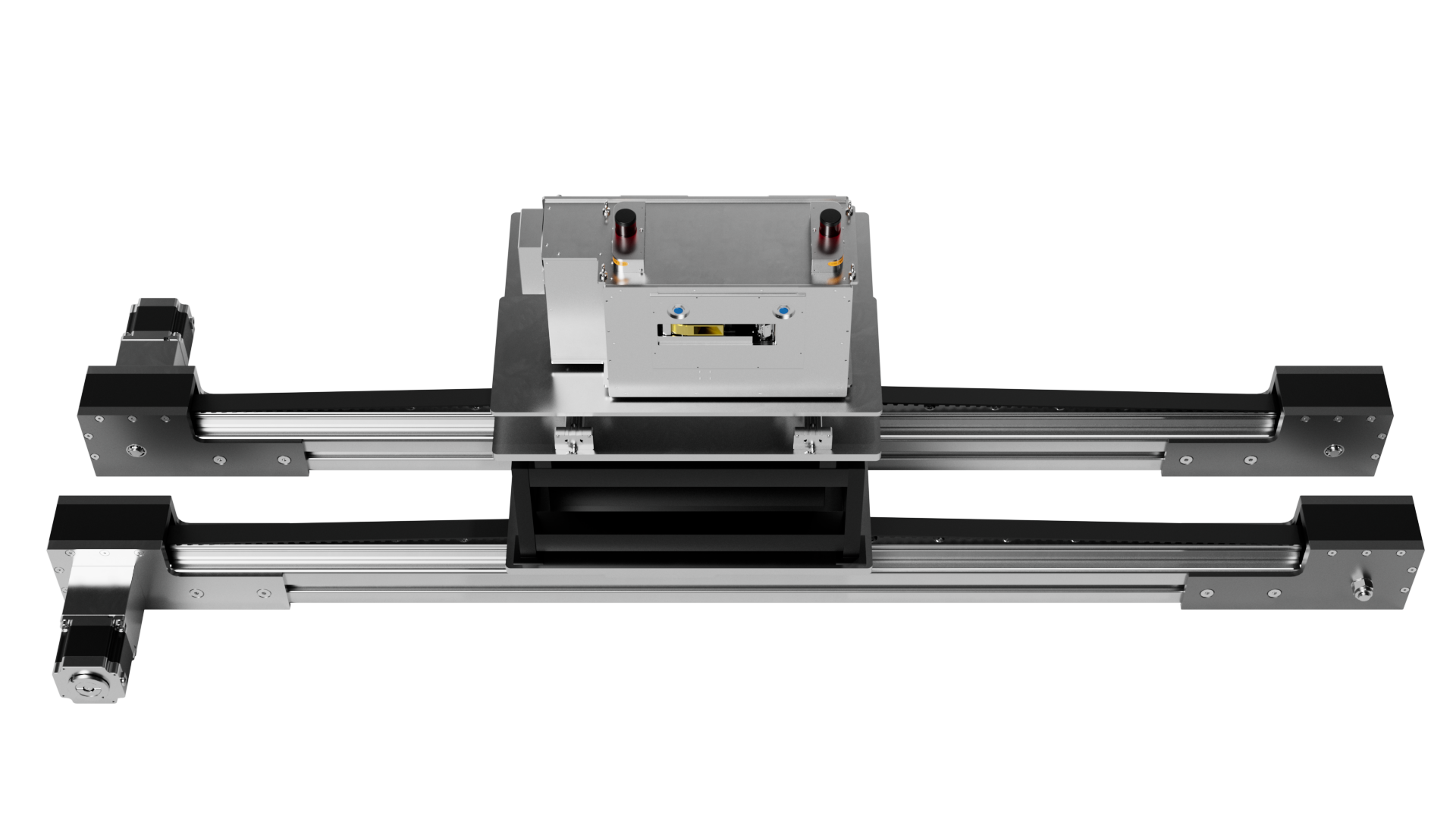

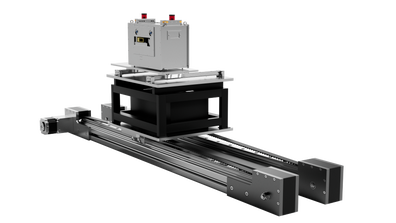

Quick and easy set-up: On-line XRD can be installed in a single day, for example during planned maintenance, getting you up and running with no disruption to your production process

-

Lower environmental impact: With On-line XRD, you can avoid the wasted energy and raw materials that come with re-melting your steel coil, helping you meet the growing demand to reduce the environmental impact of your operations

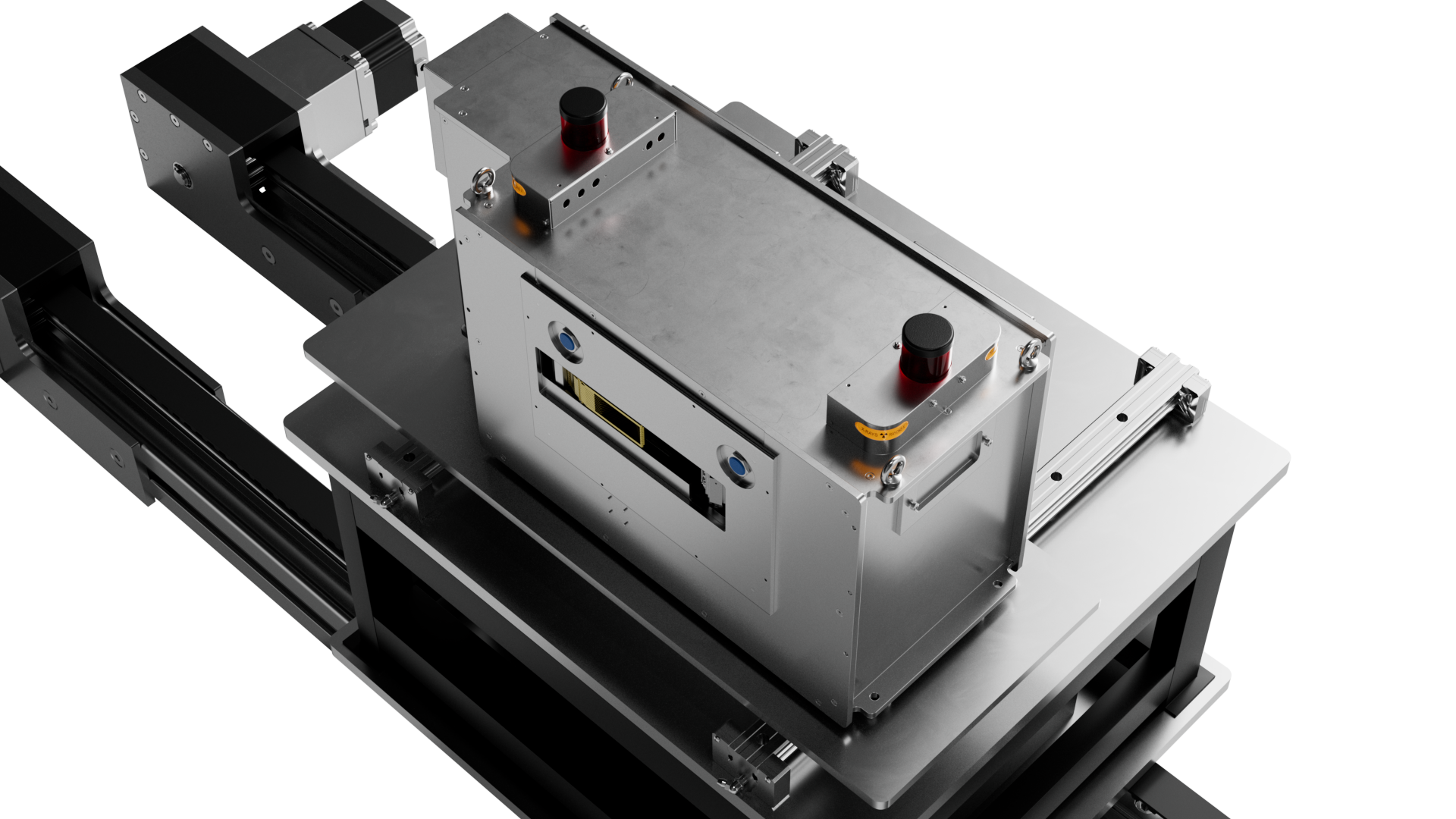

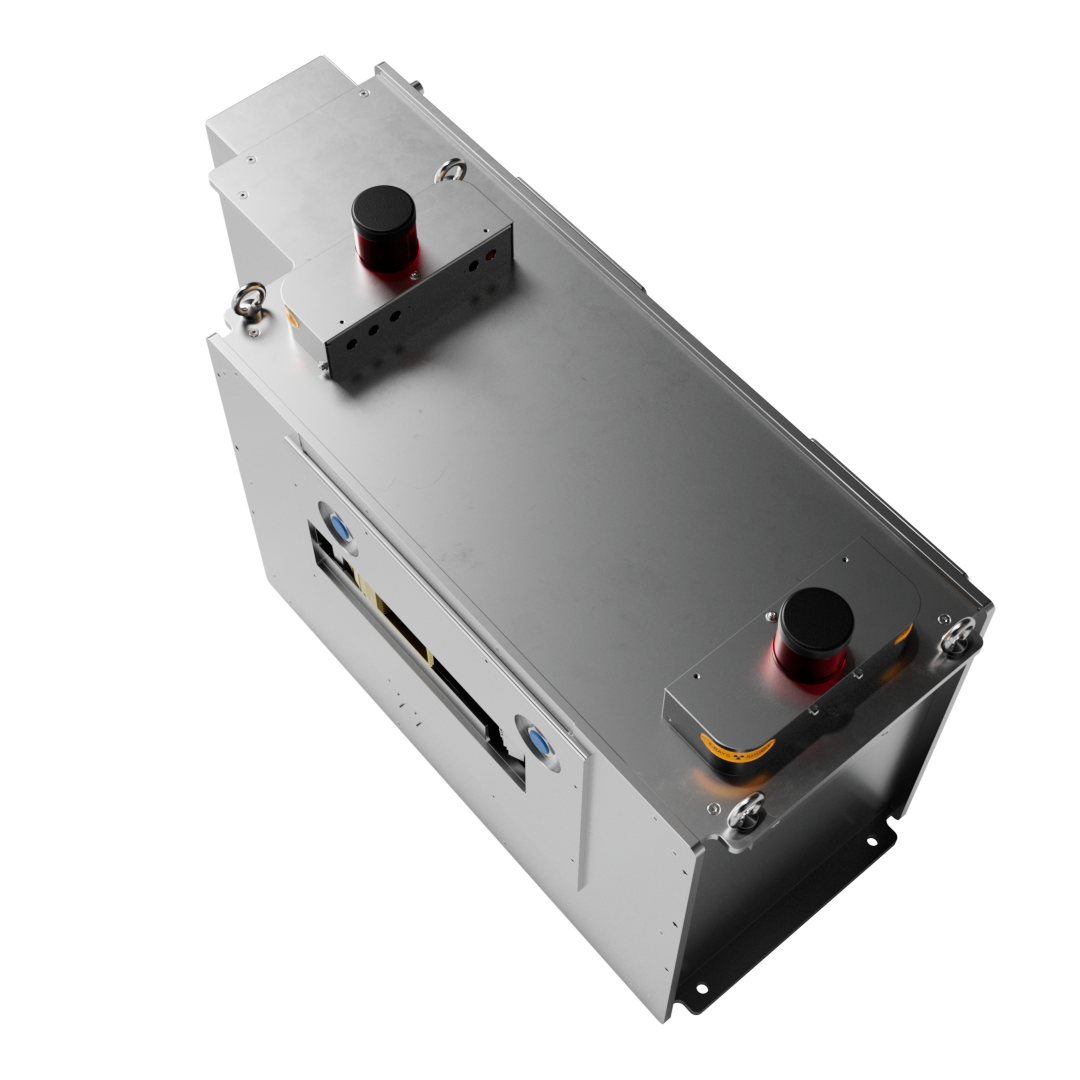

Fast, reliable analysis

Crystallographic data from XRD are ideal for analyzing galvannealed steel – but with Malvern Panalytical on-line XRD there’s no need to wait eight hours for the results of an off-line sample. Our game-changing on-line solution means you can monitor critical process parameters in real time, from crystallographic phase composition to layer thickness. Plus, this instrument provides close-to-lab-quality sensor measurements, so you know you’re getting results you can rely on.

All this enables you to more quickly identify and resolve any problems in your steel galvannealing, gaining important time, energy, and materials savings: great news not only for your site’s cost efficiency but also for the environment.

Layer thickness and phase composition

- Online/Inline, real-time, fully automated XRD analysis of galvannealed steel during the production process

- The new thickness analysis algorithm in HighScore 5.3 determines the individual thickness of all phases (zeta, delta, gamma1, gamma) within the galvannealed Fe/Zn layer

- Fully implemented system monitoring and intensity calibration