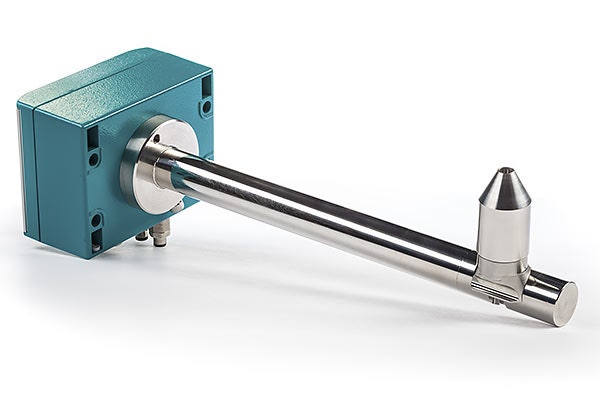

D24 inline sample disperser

Inline disperser for fine particle processes

The D24 disperser dilutes and disperses material drawn from the process, simultaneously directing it towards the measurement zone of the Parsum probe. It ensures robust and accurate sizing for particles with a Dv50 in the range 50 µm to 1.2mm, making it especially useful for direct measurement within fluidized beds.