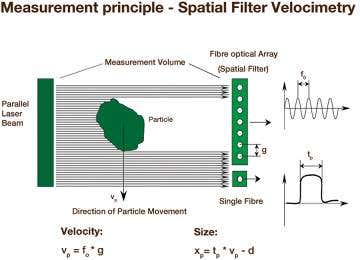

Measuring a large number of particles generates statistically valid results from which various size parameters and volume-based distributions are derived, depending on the needs of the user.

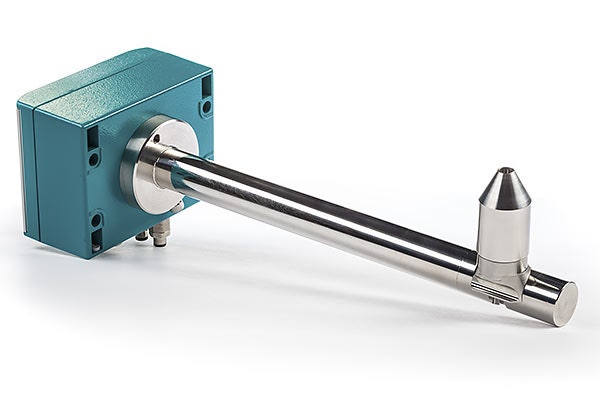

The Parsum IPP 70-SE is installed directly into the line or vessel. Although no sample preparation is required an internal compressed air supply can be used to disperse agglomerates, to keep the flow channel and optics clear of adherent material and to enable measurement at high solids loadings and temperatures.

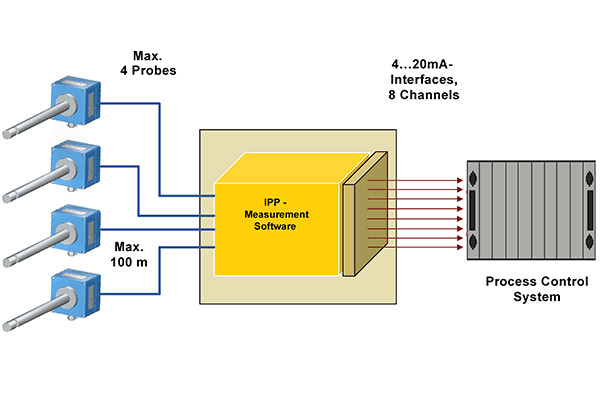

Information is transferred from the measurement zone to the electronic housing of the probe via fiber optic cable increasing instrument robustness. These data can then be transferred to the control room or indeed into an existing control system for processing monitoring and control. Because the instrument provides a measure of concentration in the sensing volume, changes in flow/throughput can be estimated, using an appropriate correlation.