Overview

The Micromeritics Sub-Sieve AutoSizer (SAS) II determines particle size, surface area, and powder bed porosity by air permeability.

Developed as a direct and modernized successor to the widely used Fisher Model 95 Subsieve Sizer (FSSS), the Micromeritics SAS II utilizes a built-in computer and touchscreen to perform measurements easily and quickly in a laboratory setting or on a production floor. Data can be saved, printed, or exported electronically in a spreadsheet or PDF format.

The Micromeritics Sub-Sieve AutoSizer II generates “Fisher number” results highly consistent with those of its predecessor (the Fisher FSSS), using the built-in Fisher Mapping feature. This is a crucial point, as the air permeability technique and the FSSS have been used as a benchmark for decades in many industries. Many applications use historical data and quality control standards, and a modern source of comparable, repeatable results is necessary.

Why SAS?

-

- Fully automated analysis

-

Sample compaction and pressure stability are computer-controlled for high repeatability

- Fisher mapping

-

Optimizes data agreement with customizable Fisher correlation

- Report generation

-

Automatically creates PDF reports with custom company logos and typestyles

- Superior software

-

The SAS Software sets a world-wide standard for instrument operation, data acquisition and handling, reporting and systems integration

- New intuituve touchscreen

-

Powerful, intuitive touchscreen user interface increases productivity and enables easy creation and retrieval of SOPs

- ASTM approval

-

Fully compliant with:

- ASTM standard B330-12

- B330-15 – Metal Powders

- C721-15 – Al2O3, SiO2 – Ceramics

- E2980 – 15 – General particle size

What is air-permeability particle sizing?

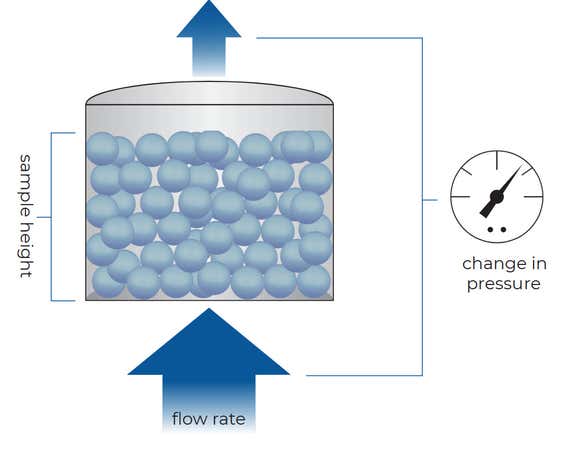

The air-permeability technique is well established for the measurement of the specific surface area of a sample powder. The specific surface area measured by this technique is a useful parameter in various industries such as pharmaceutical, metal coatings, paints, and even geological samples.

The Micromeritics SAS II utilizes dual pressure transducers to measure pressure drop across a packed bed of powder.

By varying the sample height and porosity while controlling the flow rate of air through the sample, the specific surface area and average particle size can be determined using the Kozney-Carmen equation.

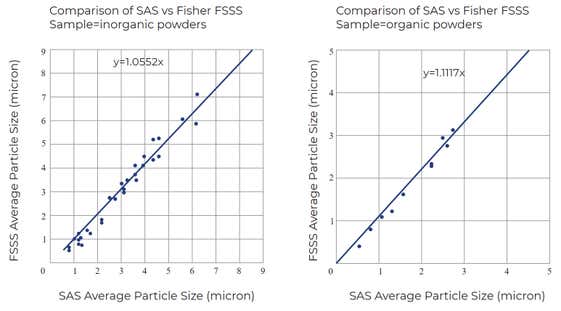

Direct comparison: SAS & FSSS results

Comparison trials between the MIC SAS II and Fisher FSSS have been carried out using a variety of samples.

These graphs compare the mean particle size data from the two instruments on powders of different sizes. One plot is based on results for inorganic (mainly tungsten) metal; the second on organic samples (mostly pharmaceuticals).

There is an exceptional correlation between the two sets of data; numerous extensive studies have come to the same conclusion.