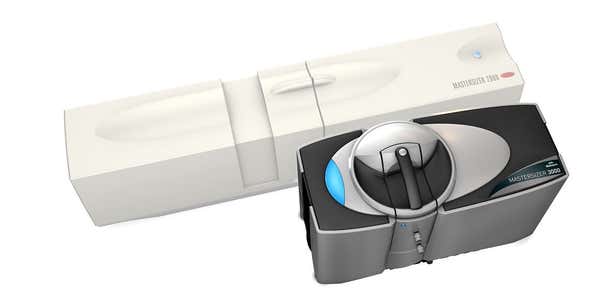

Hydro 2000G

Large volume automated wet dispersion accessory.

The Hydro 2000G is a fully automated large volume wet sample dispersion unit. It is most suitable for QC applications where representative sampling is important, as well as the measurement of polydisperse samples with very broad particle size distributions.