Liposome- and nanoparticle-based drug product formulation

Physicochemical analysis solutions to support nanopharmaceutical formulation

Physicochemical analysis solutions to support nanopharmaceutical formulation

Reliable characterization techniques are fundamental to enabling and advancing the use of nano-sized materials in pharmaceutical products. The intense investigation of nanoparticles (particles in the size range 10 nm to 1000 nm), and their increasing use as drug delivery vehicles, requires the application of a variety of physicochemical characterization techniques to support complete understanding and control of critical parameters.

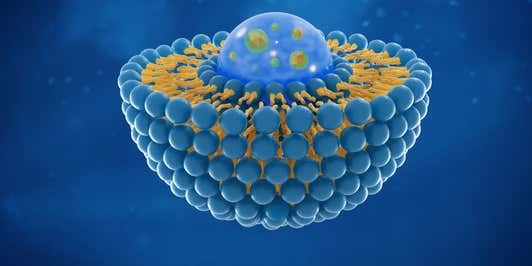

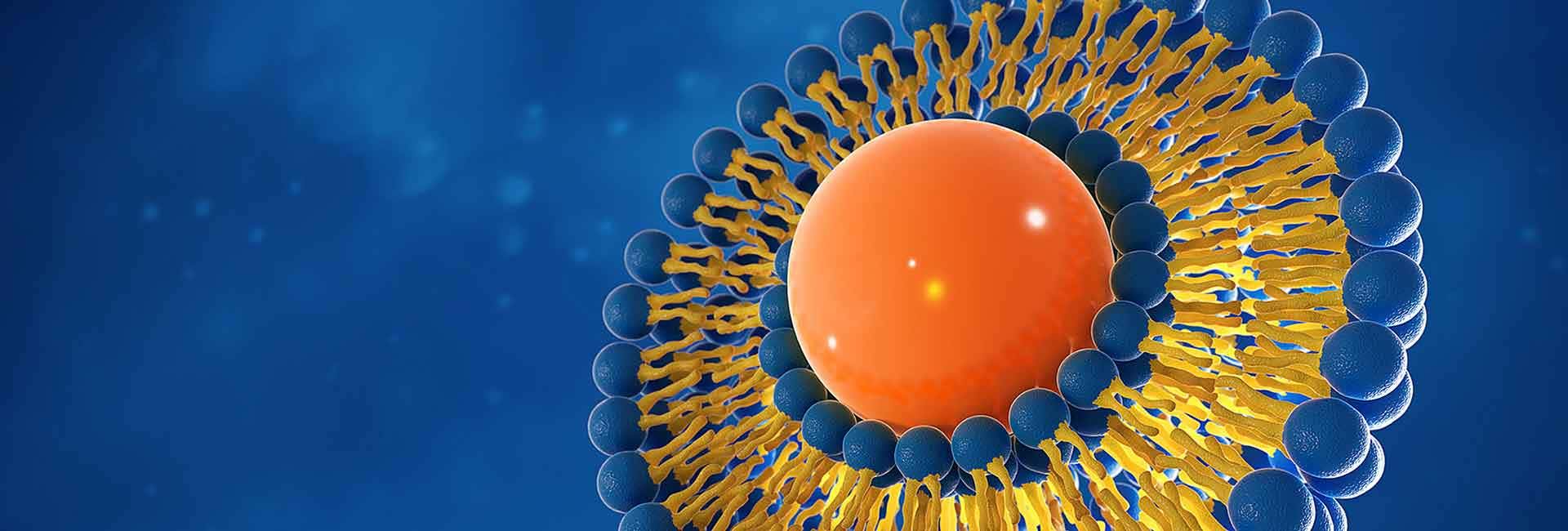

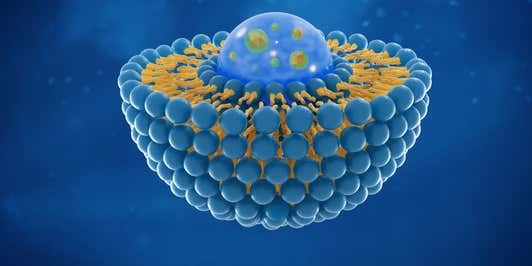

In formulation development and drug delivery, the term ‘nanoparticles’ refers to a variety of particles used to deliver drug products or proteins to their target site. These include liposomes, solid lipid nanoparticles (SLNs) micelles and polymeric nanoparticles. The physicochemical state of the nanomaterial-drug complex is often critical, impacting in vivo pharmacokinetics, release and functioning of the drug. Full characterization of a range of parameters is needed during development and manufacturing to ensure effective process control and the delivery of safe medicines. For nano-sized drug delivery vehicles, size and size distribution, shape and composition are often integral to successful function, since these characteristics may influence the ability of a carrier to reach its target and to deliver the drug substance effectively.

Malvern Panalytical’s range of complementary technologies for characterization at the nanoscale are widely used. They have applications from fundamental R&D, right through to manufacturing and QC, to characterize, monitor and control critical features of nano-sized materials, pharmaceutical formulations and drug products.

Development of nanoparticle drug carriers often involves making additions to the main particle component. For example, cholesterol may be added to liposomes to improve their stability, or particle surfaces may be functionalized using PEG or other polymers to extend circulation times in the body.

Such particle modifications are intended to improve the features of a drug carrier, but must be carefully controlled. Monitoring and optimizing the addition of modifying materials is essential in order to contain costs and, more importantly, to ensure that particle stability is not adversely affected.

Malvern Panalytical’s well-established solutions for nanoparticle size, zeta potential and concentration measurements provide a highly effective toolkit for formulation development. This toolkit allows monitoring and optimization of formulations to determine operating ranges and parameters, as well as to improve the quality and functionality of the nanoparticle formulation.

The thermal stability and phase behavior of liposomes and other nanoparticles often reflects their in vivo stability and drug release characteristics. These properties can be affected by the added components, including the drug itself, making it important to understand the structure and dynamics of the system as a whole.

Malvern Panalytical’s Differential Scanning Calorimetry (DSC) and X-ray diffraction (XRD) systems deliver critical information for mapping liposome phase behavior and understanding lamellar composition.

The internal structure of many drug carriers can affect their drug release properties and/or their physical stability. Understanding and controlling the influential factors is important in selecting appropriate drug delivery vehicles and achieving effective, stable drug formulations.

Malvern Panalytical offers analytical technologies that enable characterization of drug carrier compositions. Applications range from investigating the lamellar structure of liposomes to understanding the copolymer structure of polymer particles.

Successful drug delivery using a carrier requires not only effective loading of the drug substance but also a detailed understanding of how the loaded carriers behave under a variety of different conditions. The effects of processing, storage and transport, and the behavior of the drug-carrier complex under physiological conditions must all be studied.

Nanoparticle tracking analysis (NTA) is widely applied to investigate the efficiency of drug encapsulation protocols and the consequent stability of drug-carrier complexes. Using fluorescence labeling, NTA can monitor the size of the drug-carrier complex. These measurements can be extended for use in physiological fluids to probe the stability of the drug-carrier complex under these conditions.

Ensuring the stability and functionality of nanoparticle formulations through scale-up and process optimization, manufacturing and end-use of the product requires continued monitoring of critical parameters.

The size of liposomes and other nano-sized drug delivery vehicles is critical to their function. Nanoparticle size is a key quality attribute that is often exploited or manipulated to achieve the desired biological response. It is an important process parameter that must remain constant from development through to nanomedicine use. Monitoring size and possible size changes throughout the formulation lifetime is critical, irrespective of the manufacturing process.

Multi-Angle Dynamic Light Scattering (MADLS), classical dynamic light scattering (DLS) and nanoparticle tracking analysis (NTA) are used to elucidate any changes in particle size and concentration that may occur during standard processing steps, such as freeze-thawing, homogenization and reconstitution after lyophilization.

Another key quality attribute that influences the functionality of a nanoparticle formulation is the nanoparticle charge. This is often linked to the strength of the immune response and is a parameter that needs to be monitored when using charged lipids.

Dynamic light scattering technology enables measurement of zeta potential to indicate the overall charge of a formulation, which is relevant throughout R&D, manufacturing and end-use of the formulation. Changes to the formulation charge at any stage throughout the lifetime of the product have the potential to impact the effectiveness of the nanomedicine and therefore require careful monitoring.