NEW ChemiSorb Auto: +/-1 % repeatability, ultra-low void volume and automated workflows. Essential Chemisorption. Ultimate Value. Find out more

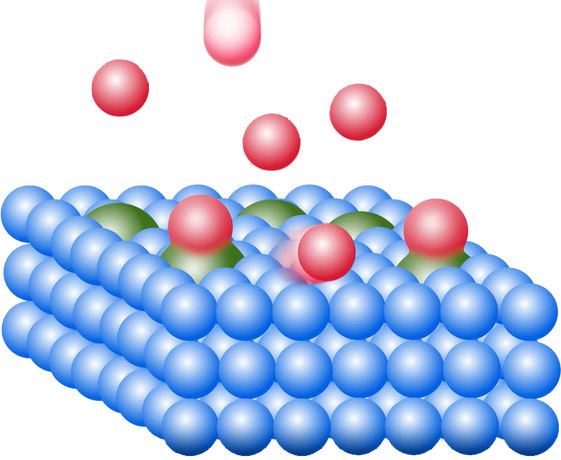

Find out moreChemisorption, or chemical adsorption, is a surface-specific process where a gas or vapor molecule forms a strong chemical bond with a solid material's surface. This interaction involves electron sharing or transfer, resulting in a new chemical species at the interface.

Unlike physisorption, which is governed by weaker van der Waals forces, chemisorption is characterized by higher binding energies and is typically irreversible under standard conditions.

This phenomenon is crucial in catalyst characterization, providing insights into:

The two main techniques for chemisorption analysis are static volumetric chemisorption, and dynamic flow chemisorption.

In this method, gas adsorption is measured at various pressures while maintaining a constant temperature. By analyzing the amount of gas adsorbed, we can determine the number of active sites on a material's surface. This technique is valuable for calculating parameters like metal dispersion and active surface area.

This approach involves passing a reactive gas over the sample and monitoring the interaction in real-time. It allows for the assessment of active site strength and distribution, as well as the evaluation of reaction mechanisms. Dynamic methods are particularly useful for studying temperature-programmed reactions and pulse chemisorption experiments.

A chemisorption analyzer is a sophisticated scientific instrument used to measure the interaction between a solid surface and gas molecules, particularly focusing on chemical bonding. It plays a crucial role in various industries such as catalysis, material science, and environmental monitoring by providing detailed insights into surface properties and reaction mechanisms. Chemisorption analyzers utilize precise techniques like temperature-programmed desorption (TPD), temperature-programmed oxidation (TPO), temperature-programmed surface reactions (TPSR), and pulse chemisorption to characterize catalysts, adsorbents, and nanoparticles, aiding in the development of advanced materials and optimized processes.

The techniques of chemisorption encompass a range of sophisticated methods employed in scientific research and industrial applications. These techniques include temperature-programmed desorption (TPD), temperature-programmed oxidation (TPO), temperature-programmed surface reactions (TPSR), and pulse chemisorption. Each technique offers unique insights into the interaction between solid surfaces and gas molecules, aiding in the characterization of catalysts, adsorbents, and nanomaterials. By employing these advanced techniques, researchers and engineers can gain valuable information essential for optimizing processes and developing innovative materials across various industries.

As of the latest developments, the current sample size for chemisorption analysis varies depending on the specific instrument and application requirements. However, modern chemisorption analyzers typically accommodate sample sizes ranging from a few milligrams to several grams. These versatile instruments are capable of analyzing a wide range of materials, including catalysts, adsorbents, and nanoparticles, offering researchers and engineers the flexibility needed for comprehensive surface characterization and reaction studies. By leveraging the appropriate sample size, scientists can obtain accurate data crucial for optimizing processes and advancing research in fields such as catalysis, material science, and environmental monitoring.

Our suite of chemisorption analyzers is designed to provide comprehensive insights into material surfaces:

These instruments support a range of applications, from catalyst development to material science research, providing accurate and reliable data for informed decision-making.

We provide a comprehensive range of characterization services whether it is the analysis of a single sample, a complex method development or validation, new product assessments, or addressing large-scale manufacturing projects.

Available options

Chemisorption Tests:

Temperature-Programmed Studies:

Other Chemisorption Experiments: