Double the capacity. Half the cost. Upgrade your research now with our exclusive Buy One Get One FREE instrument packages. Find out more

Find out morePorosimetry encompasses a suite of analytical techniques designed to characterize the porous architecture of materials.

By examining attributes such as pore size, volume, and distribution, these methods provide critical insights into material performance across various applications, including pharmaceuticals, energy storage, filtration, and advanced materials research.

![[Porosimetry measurement Blind-Pore-diagram.png] Porosimetry measurement Blind-Pore-diagram.png](https://dam.malvernpanalytical.com/258e1d15-515e-4545-abbf-b2f900949fe1/Porosimetry%20measurement%20Blind-Pore-diagram_Original%20file.png)

|

![[Porosimetry measurement Through-Pore-diagram.png] Porosimetry measurement Through-Pore-diagram.png](https://dam.malvernpanalytical.com/6ecb9092-d563-4c2f-82c5-b2f900949e5c/Porosimetry%20measurement%20Through-Pore-diagram_Original%20file.png)

|

![[Porosimetry measurement Closed-Pore-diagram.png] Porosimetry measurement Closed-Pore-diagram.png](https://dam.malvernpanalytical.com/fef962df-9a95-4891-bf25-b2f90094a050/Porosimetry%20measurement%20Closed-Pore-diagram_Original%20file.png)

|

||

|

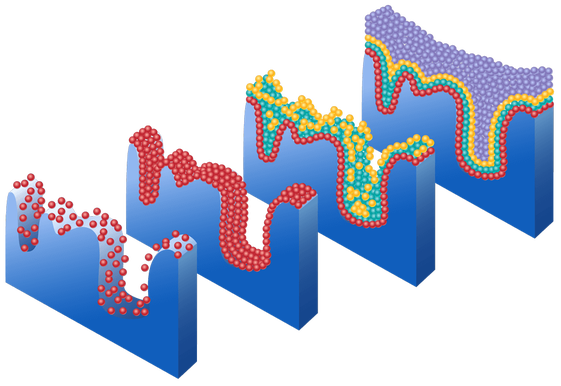

Blind pores

|

Through pores

|

Closed pores

|

This technique involves the controlled application of pressure to force mercury, a non-wetting liquid, into the pores of a material.

By measuring the volume of mercury intruded at each pressure increment, one can derive comprehensive data on pore size distribution, total pore volume, surface area, and material densities.

The method is particularly effective for analyzing pore sizes ranging from 3 nanometers to 600 micrometers.

Also known as gas-liquid porometry, this method assesses the size and distribution of through-pores by displacing a wetting liquid within the material's pores using gas pressure. The pressure at which gas first permeates the sample (the bubble point) indicates the largest pore size, while subsequent flow measurements reveal the distribution of smaller pores.

This technique is advantageous for its speed, reliability, and the absence of hazardous materials like mercury.

![[AccuPore - Micromeritics - increase-pressure-graphic.jpg] AccuPore - Micromeritics - increase-pressure-graphic.jpg](https://dam.malvernpanalytical.com/ad9eeeaf-d792-4904-b022-b26b00ffd87e/AccuPore%20-%20Micromeritics%20-%20increase-pressure-graphic_Original%20file.jpg)

Gas adsorption methods, including BET surface area analysis, involve measuring the amount of gas adsorbed onto a material's surface at various pressures.

These techniques are instrumental in determining surface area, pore volume, and pore size distribution, especially in microporous and mesoporous materials.

We provide a comprehensive range of characterization services whether it is the analysis of a single sample, a complex method development or validation, new product assessments, or addressing large-scale manufacturing projects.

Available options