Insitec 2000 installation guide (English)

Version number: MAN0311-06-EN-00

Looking for more information?

To request a quote, more information or download a brochure select an option below.

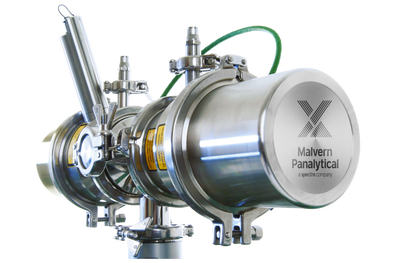

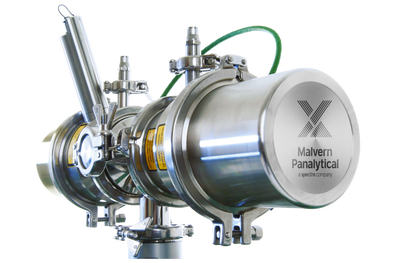

Engineered to withstand the rigors of the process environment, Insitec Wet particle size analyzers use laser diffraction technology to measure particles in the size range 0.1 to 2500 µm in emulsions, suspensions and slurries. Insitec Wet can be configured to suit practically every wet particulate process, delivering real-time monitoring and control 24/7.

Insitec Wet particle size analyzers deliver fully automated real-time - or manual at-line - size measurement of particulates in batch or continuous wet processes. They are used to monitor and control suspensions, emulsions and slurries in a number of industries, from hot sticky highly concentrated mineral streams to dilute lipid pharmaceutical emulsions.

To ensure representative sampling, process interfaces are tailored to meet customer needs - whether pilot scale or hundreds of tonnes per hour.

Integration with existing control platforms to simplify development of automated control protocols

High reliability of >95% with little downtime, minimal maintenance and maximum ROI

Easy-to-use software and fully automated operation to minimize training requirements and release operator time

Base model hardware manufactured to GAMP5 standards and compatible with CIP/SIP requirements to meet specific manufacturing specifications

All Insitec installations are tailored to the unique requirements of the application. They range from simple at-line, manually-fed systems to fully automated, validated on-line solutions for continuous monitoring and multivariate control.

Malvern Panalytical works in partnership with its customers, providing expertise, hardware and software, where and when it’s needed. This ensures cost-effective, successful project implementation and a positive return on investment.

The success of process analysis depends on detailed consideration of three critical components:

Insitec process equipment operates within the plant environment. Getting the interface between the instrument and the plant right is essential for long-term, trouble-free operation.

Malvern Panalytical has proven technology for almost every conceivable wet process application. From integrated sample dilution hardware incorporating multistage cascade diluters, for highly concentrated slurries, to simple static samplers for more dilute suspensions and emulsions. Proven strategies ensure that representative samples are automatically and consistently delivered to the measurement zone, in an appropriately dispersed state and at a suitable concentration for analysis.

Insitec at-line systems run alongside the process and have a manual interface. For automated continuous operation, Insitec is installed in the process line or on an associated sampling loop.

Measurement in an appropriately dispersed state ensures access to relevant data, whether it is agglomerates or primary particle size that is of interest.

A dedicated Insitec may be necessary for each measurement point, or it may be possible to monitor multiple lines or process steps with a single sensor. This depends on the measurement frequency required.

Well-designed on-line process interfaces:

Insitec systems use the technique of laser diffraction to rapidly measure particle size. When applied to wet systems, complete particle size distributions can be measured in less than one second, giving instantaneous monitoring. Even processes with fast dynamics can be tracked effectively.

Insitec directly measures the process stream. Many wet processes have high solids loadings making dilution an essential precursor to laser diffraction measurement. However, the patented multiple scattering algorithms associated with all Insitec systems extend the working concentration range of the technique. These algorithms mathematically correct for the concentration-dependent effect of the source light interacting with not one, but several, particles before reaching the detectors. More samples can be measured without dilution; concentrated solutions require less pre-treatment. And all measurements are robustly independent of sample concentration.

Insitec produces reliable, timely and complete data, reporting full particle size distributions. These data provide a secure foundation for better process control whether that control is manual or automated.

Insitec systems are integrated within the process plant. Typically they are operated from a centralized control room and the measurement results drive routine decision making. Powerful software packages make integration and data interpretation straightforward.

Malvern Link II software provides the functionality required to integrate an Insitec within the existing control system and to automate process control. It allows operation from either a dedicated PC or from existing control mimics. Malvern Link II is not confined only to Insitec integration; it also eases integration with other instrument types, simplifying multivariate control.

RTSizer software presents measurement data in a clear, accessible way. Results reporting can be tailored to industry and customer norms to improve information flow. Insitec data are used to:

Because complete particle size distributions are reported, monitoring and control can be based on whichever size fraction is of interest (e.g. fines, 3-30 µm fraction, amount of material over 200 µm). Insitec data drives optimized manual control strategies and enables automation of process control, delivering substantial economic returns.

Insitec Wet can be configured to suit practically every wet particulate process, even in gas or dust zoned hazardous environments.

| Measurement type | Particle size |

|---|---|

| Measurement range | 0.1 to 2500µm |

| Measurement principle | Laser diffraction |

| Optical models | Mie theory |

| Accuracy | ±2% on Dv(50) reported using the verification reticle |

| Power | 100/240V |

|---|---|

| Enclosure rating | IP65 |

| Operating platforms | 10 bar (g) |

| Software | RTSizer (for instrument control) Malvern Link II (for system automation and data link) |

| Maximum distance from instrument to PC | 500m (up to 2 km using fiber optics) |

| Temperature | 10°C – 70°C |

|---|---|

| Humidity | 35% - 80% (non-condensing) |

Version number: MAN0311-06-EN-00

Version number: MAN0663-01

Version number: MAN0662-01-EN

Version number: MAN0484-02-EN

Version number: MAN0472-03

Version number: MAN0470-03-EN

Version number: MAN0471-03-EN

Version number: MAN0473-03-EN

Version number: MAN0304G-3-0

Version number: MAN0351G-2-0

Version number: MAN0304F-3-0

Version number: MAN0351F-2-0

Version number: MAN0304-3-1

Version number: MAN0440-1-1

Version number: MAN0375-1-0

Version number: MAN0467-1-0

Version number: MAN0468-1-0

Version number: MAN0466-1-0

Version number: MAN0311-04-DE-01

Version number: MAN0311-04-FR-01

Version number: OP-IPP70-nov11

Version number: HW-IPP70-nov11

Insitec 2000 RT Sizer software

Insitec 2000 RT Sizer software

Insitec 2000 RT Sizer software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Bug fix enabling updates to IMDdata values from WinWrap script in customer data converter

Malvern Link II Software

To ensure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Engineered to withstand the rigors of the process environment, Insitec Wet particle size analyzers use laser diffraction technology to measure particles in the size range 0.1 to 2500 µm in emulsions, suspensions and slurries. Insitec Wet can be configured to suit practically every wet particulate process, delivering real-time monitoring and control 24/7.

Insitec Wet particle size analyzers deliver fully automated real-time - or manual at-line - size measurement of particulates in batch or continuous wet processes. They are used to monitor and control suspensions, emulsions and slurries in a number of industries, from hot sticky highly concentrated mineral streams to dilute lipid pharmaceutical emulsions.

To ensure representative sampling, process interfaces are tailored to meet customer needs - whether pilot scale or hundreds of tonnes per hour.

Integration with existing control platforms to simplify development of automated control protocols

High reliability of >95% with little downtime, minimal maintenance and maximum ROI

Easy-to-use software and fully automated operation to minimize training requirements and release operator time

Base model hardware manufactured to GAMP5 standards and compatible with CIP/SIP requirements to meet specific manufacturing specifications

All Insitec installations are tailored to the unique requirements of the application. They range from simple at-line, manually-fed systems to fully automated, validated on-line solutions for continuous monitoring and multivariate control.

Malvern Panalytical works in partnership with its customers, providing expertise, hardware and software, where and when it’s needed. This ensures cost-effective, successful project implementation and a positive return on investment.

The success of process analysis depends on detailed consideration of three critical components:

Insitec process equipment operates within the plant environment. Getting the interface between the instrument and the plant right is essential for long-term, trouble-free operation.

Malvern Panalytical has proven technology for almost every conceivable wet process application. From integrated sample dilution hardware incorporating multistage cascade diluters, for highly concentrated slurries, to simple static samplers for more dilute suspensions and emulsions. Proven strategies ensure that representative samples are automatically and consistently delivered to the measurement zone, in an appropriately dispersed state and at a suitable concentration for analysis.

Insitec at-line systems run alongside the process and have a manual interface. For automated continuous operation, Insitec is installed in the process line or on an associated sampling loop.

Measurement in an appropriately dispersed state ensures access to relevant data, whether it is agglomerates or primary particle size that is of interest.

A dedicated Insitec may be necessary for each measurement point, or it may be possible to monitor multiple lines or process steps with a single sensor. This depends on the measurement frequency required.

Well-designed on-line process interfaces:

Insitec systems use the technique of laser diffraction to rapidly measure particle size. When applied to wet systems, complete particle size distributions can be measured in less than one second, giving instantaneous monitoring. Even processes with fast dynamics can be tracked effectively.

Insitec directly measures the process stream. Many wet processes have high solids loadings making dilution an essential precursor to laser diffraction measurement. However, the patented multiple scattering algorithms associated with all Insitec systems extend the working concentration range of the technique. These algorithms mathematically correct for the concentration-dependent effect of the source light interacting with not one, but several, particles before reaching the detectors. More samples can be measured without dilution; concentrated solutions require less pre-treatment. And all measurements are robustly independent of sample concentration.

Insitec produces reliable, timely and complete data, reporting full particle size distributions. These data provide a secure foundation for better process control whether that control is manual or automated.

Insitec systems are integrated within the process plant. Typically they are operated from a centralized control room and the measurement results drive routine decision making. Powerful software packages make integration and data interpretation straightforward.

Malvern Link II software provides the functionality required to integrate an Insitec within the existing control system and to automate process control. It allows operation from either a dedicated PC or from existing control mimics. Malvern Link II is not confined only to Insitec integration; it also eases integration with other instrument types, simplifying multivariate control.

RTSizer software presents measurement data in a clear, accessible way. Results reporting can be tailored to industry and customer norms to improve information flow. Insitec data are used to:

Because complete particle size distributions are reported, monitoring and control can be based on whichever size fraction is of interest (e.g. fines, 3-30 µm fraction, amount of material over 200 µm). Insitec data drives optimized manual control strategies and enables automation of process control, delivering substantial economic returns.

Insitec Wet can be configured to suit practically every wet particulate process, even in gas or dust zoned hazardous environments.

| Measurement type | Particle size |

|---|---|

| Measurement range | 0.1 to 2500µm |

| Measurement principle | Laser diffraction |

| Optical models | Mie theory |

| Accuracy | ±2% on Dv(50) reported using the verification reticle |

| Power | 100/240V |

|---|---|

| Enclosure rating | IP65 |

| Operating platforms | 10 bar (g) |

| Software | RTSizer (for instrument control) Malvern Link II (for system automation and data link) |

| Maximum distance from instrument to PC | 500m (up to 2 km using fiber optics) |

| Temperature | 10°C – 70°C |

|---|---|

| Humidity | 35% - 80% (non-condensing) |

Version number: MAN0311-06-EN-00

Version number: MAN0663-01

Version number: MAN0662-01-EN

Version number: MAN0484-02-EN

Version number: MAN0472-03

Version number: MAN0470-03-EN

Version number: MAN0471-03-EN

Version number: MAN0473-03-EN

Version number: MAN0304G-3-0

Version number: MAN0351G-2-0

Version number: MAN0304F-3-0

Version number: MAN0351F-2-0

Version number: MAN0304-3-1

Version number: MAN0440-1-1

Version number: MAN0375-1-0

Version number: MAN0467-1-0

Version number: MAN0468-1-0

Version number: MAN0466-1-0

Version number: MAN0311-04-DE-01

Version number: MAN0311-04-FR-01

Version number: OP-IPP70-nov11

Version number: HW-IPP70-nov11

Insitec 2000 RT Sizer software

Insitec 2000 RT Sizer software

Insitec 2000 RT Sizer software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Malvern Link II Software

Bug fix enabling updates to IMDdata values from WinWrap script in customer data converter

Malvern Link II Software

To ensure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Continuous particle size analysis for batch or continuous wet processes. Tailored to your unique application. Designed for tough environments.