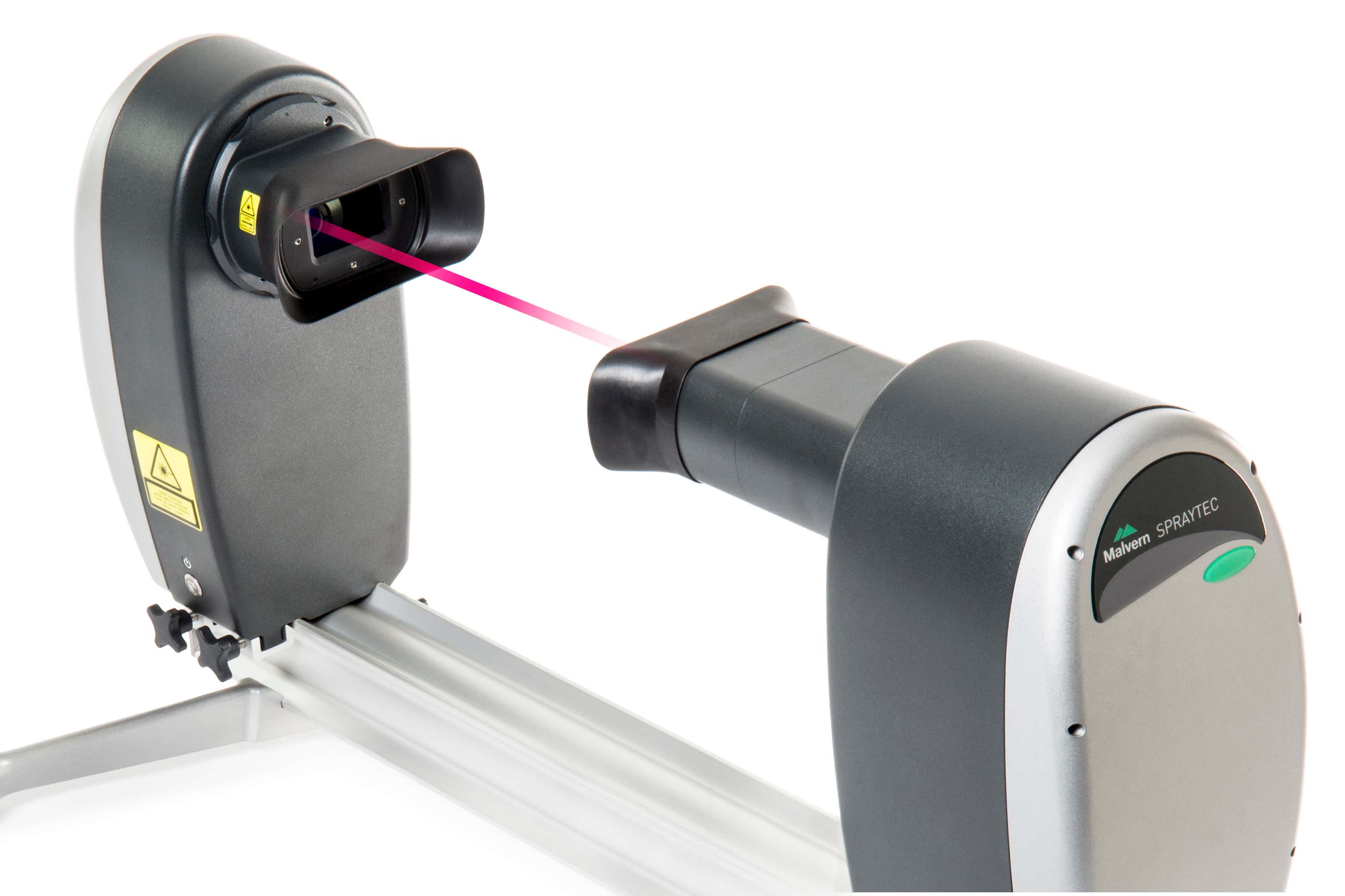

Aerosol Positioning Accessory

The Malvern Panalytical Spraytec aerosol positioning accessory enables users to reproducibly position aerosol cans or pump sprays relative to the Spraytec laser diffraction measurement zone during spray droplet and particle size measurements.

This helps to eliminate a significant source of variability associated with spray measurements, enabling the reproducible testing of domestic and personal aerosol products.