In vitro bioequivalence (IVBE)

Physicochemical characterization solutions to ensure Q3 microstructural equivalence

Physicochemical characterization solutions to ensure Q3 microstructural equivalence

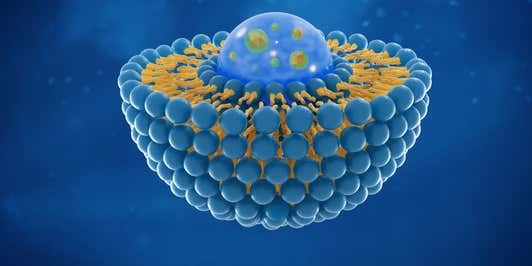

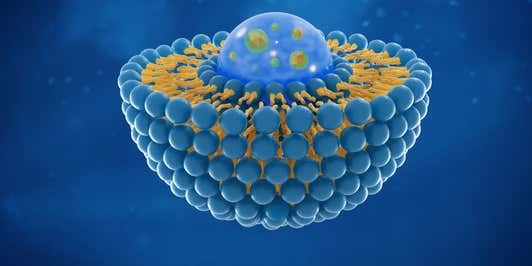

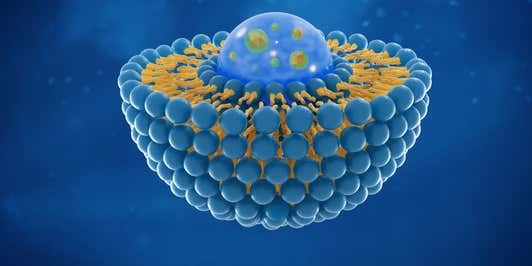

The increasing complexity of drug formulations is driving the application of in vitro bioequivalence (IVBE) testing - the process of using in vitro techniques to assess a test product’s bioavailability and bioequivalence to the reference listed drug (RLD) product - to help optimize and accelerate drug development. Underlying this trend is a recognition of the importance of formulation microstructure in controlling drug delivery and release.

A number of physicochemical properties are key to understanding a pharmaceutical formulation’s microstructure. These include globule and particle size distribution, particle charge, polymorphic form, phase behavior, particle morphology and molecular structure. Characterizing, controlling and optimizing these parameters helps drive development success by enabling detailed understanding of how the structure and properties of the formulation affect the processing and performance of the drug product.

Malvern Panalytical’s toolkit of physicochemical analysis techniques and expertise enables assessment of the properties of active pharmaceutical ingredients (API), excipients and drug product formulations. This toolkit encompasses solutions for composition analysis, morphological characterization and determination of the structure and interaction between components. All have a critical role, not only in enabling successful IVBE studies but also in gaining the essential understanding of a formulation’s stability and performance that provides the basis for more focused optimization.

Achieving reproducible drug delivery is a significant challenge, as increasingly complex formulations are applied to address challenges such as low API solubility, modified release, and localized or targeted delivery requirements. Complex drug products may be defined as those that involve one or more of the following:

Physicochemical analysis supports the development of complex formulations through elucidation of the drug, excipient and formulation microstructure. This provides developers with the insight that is needed in vitro, during formulation development and optimization, in order to achieve the required bioavailability in vivo. Microstructural analysis also aids effective scale-up to commercial manufacturing by ensuring that the critical material attributes impacting formulation performance and stability are monitored and controlled.

Malvern Panalytical offers a wide range of microstructural analysis tools and expertise essential for the development of complex formulations. These deliver the knowledge required to de-risk formulation decisions and accelerate successful formulation development.

The application of in vitro bioequivalence approaches is recognized by regulators as a key enabler for the effective development of complex generic drug formulations. The US FDA and other regulators have issued product-specific guidance that highlights the role of assessing physicochemical (Q3) equivalence as part of establishing the bioequivalence of a test generic product with a reference listed drug (RLD) product. By removing the need for clinical endpoint studies, this approach can significantly reduce the time to market for new generics.

Malvern Panalytical’s physicochemical characterization toolset provides the advanced analytical techniques and expertise needed to support essential bioequivalence studies. It also delivers capability beyond basic regulatory requirements, providing targeted physicochemical analysis that allows greater understanding of the composition, behavior and stability of a formulation. Such exploration and insight into the formulation design space helps simplify prototype formulation optimization, reducing the number of experiments required to reach the optimal formulation and reducing the risk of failures during scale-up.

During the commercial phase of a drug product’s lifecycle there may be a requirement to modify its manufacturing process. This may, for example, be a response to changes in the source of critical raw materials or intermediates. Alternatively, there may be a need to move manufacturing to another facility, or possibly outsourcing partner, in response to changes in demand for a given drug product. Maintaining product regulatory approval in these situations requires identification of the manufacturing and formulation elements that must be maintained to ensure product quality.

The application of in vitro bioequivalence techniques provides a realistic, science-based approach for identifying the critical material attributes associated with a drug product’s formulation, enabling the definition of a control strategy to manage post-approval changes. Malvern Panalytical’s physicochemical characterization tools, coupled with our knowledge and experience of the requirements for method validation and transfer, can help you define an appropriate analytical strategy to support change management, ensuring that product performance and safety is maintained.

Services from Amplify Analytics are available to help our customers with their physicochemical characterization challenges and the development, validation and deployment of analytical methods to support pharmaceutical formulation and manufacture.