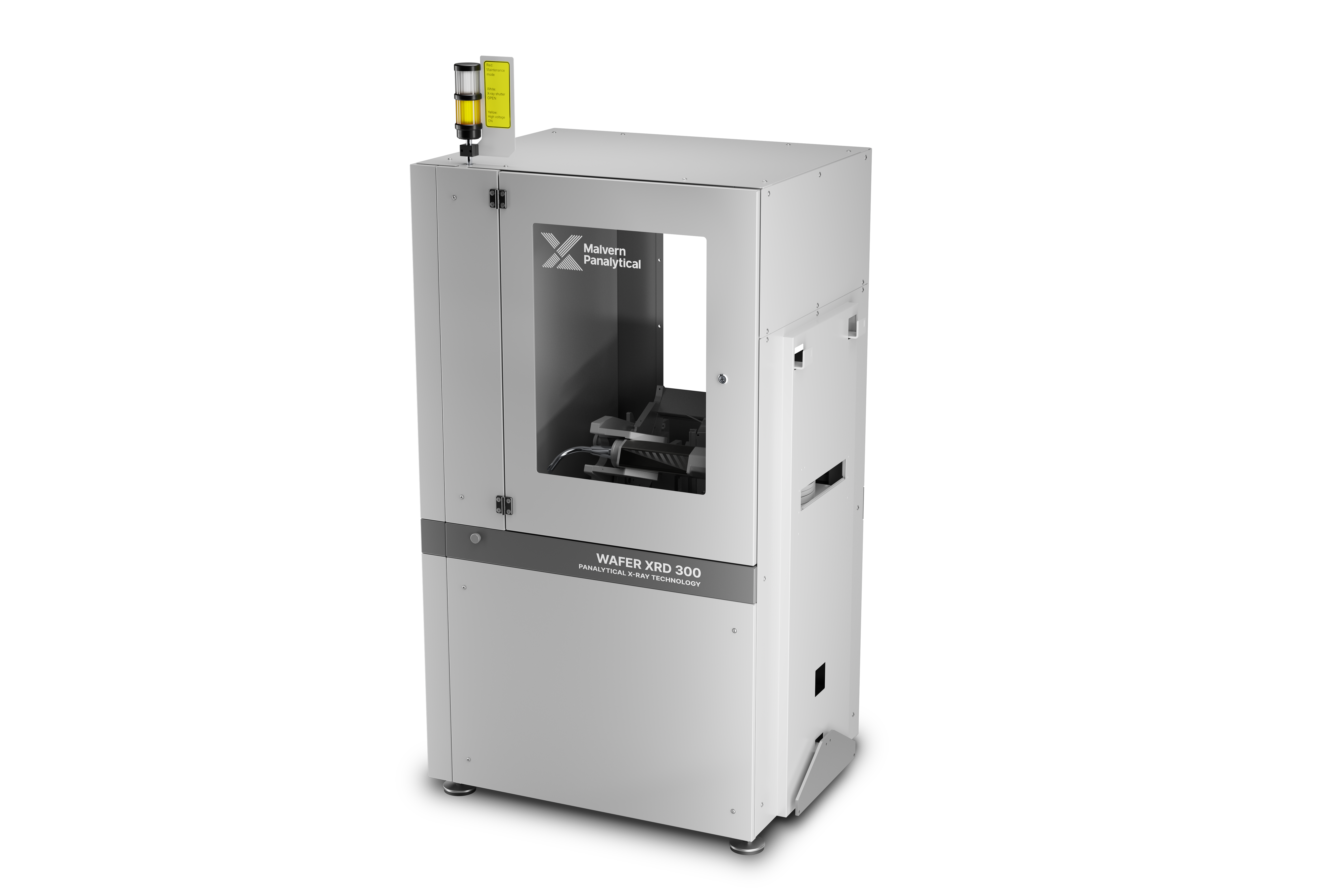

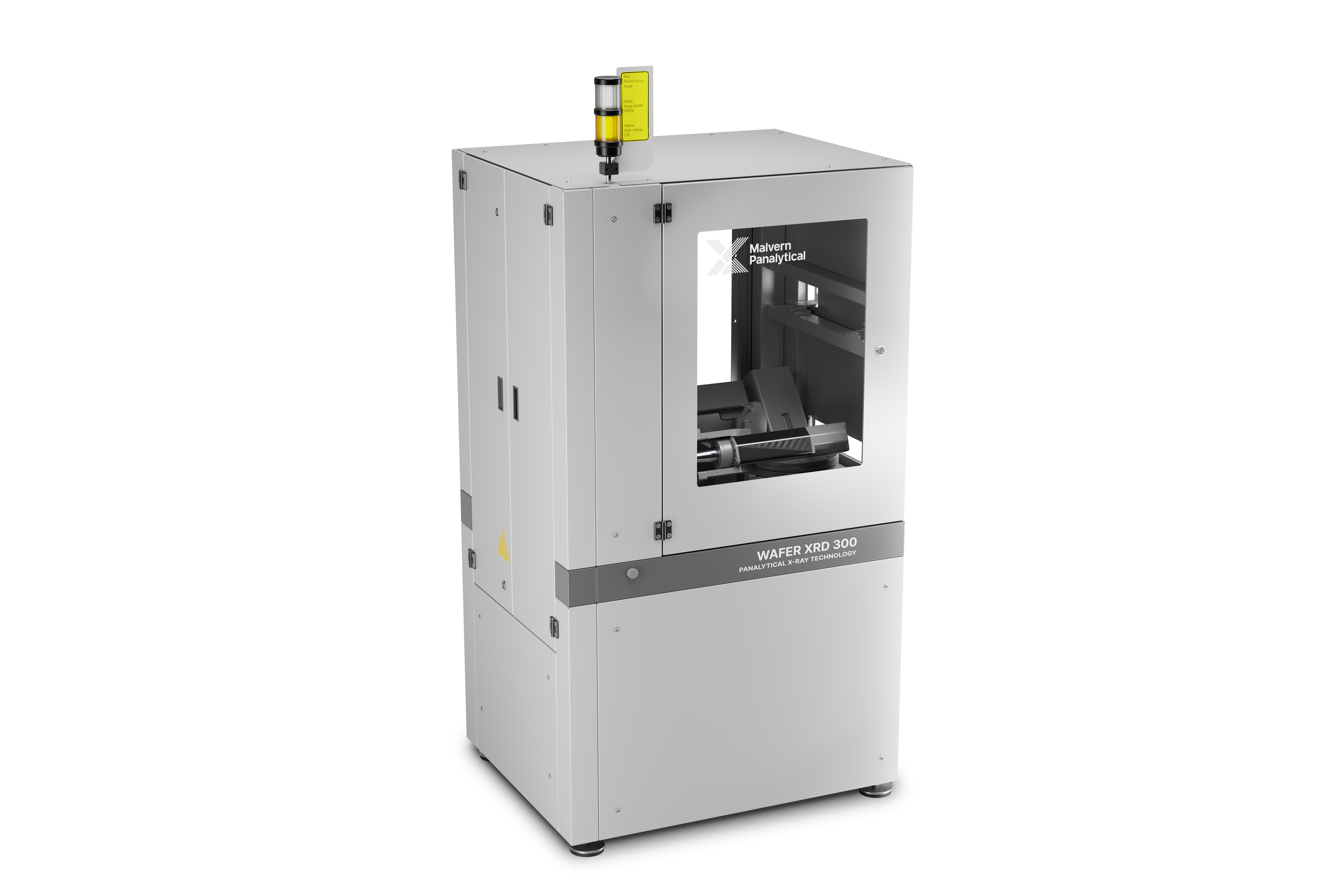

Wafer XRD 300 Pre-installation Manual

Version number: 1

Looking for more information?

To request a quote, more information or download a brochure select an option below.

Full Factory Automation is one step closer with Wafer XRD 300, an ultra-fast, high-throughput, and utmost precision wafer metrology system, ready for integration into your process line.

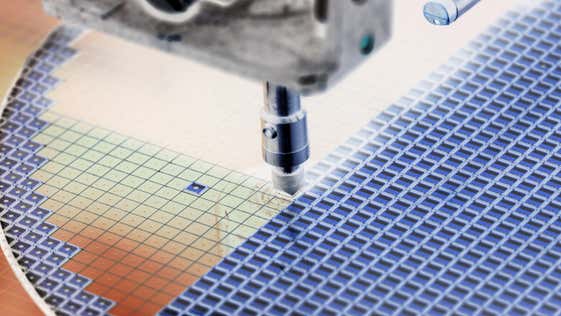

Wafer XRD 300 is a high-speed X-ray diffraction system, able to analyze 300mm wafers and provide key data such as crystal orientation, geometric features like diameter or notch position, and much more. It is designed to fit on a wafer-handling front end of your chosen processing step.

The azimuthal scan method requires only one measuring rotation to gather all the necessary data to fully determine the orientation, delivering results within 10 seconds whilst not compromising accuracy.

The sample is rotated 360°, with the X-ray source and detector positioned to achieve a certain number of reflections per turn. These reflections enable the orientation of the crystal lattice to be measured in relation to the rotation axis with a high precision of up to 0.01°.

With measurements completed in just as few as 10 seconds per sample, Wafer XRD 300 allows you to check every wafer that goes through your process, making it a powerful and efficient element in your QC process.

Operating costs are low for the Wafer XRD 300, thanks to its low energy consumption and air-cooled X-ray tube – no water cooling is required.

The instrument can be easily integrated into existing processes in production environments using its various MES, SECS/GEM, and similar interfaces.

Highly accurate in measuring your Si Wafer crystal orientation.

Wafer XRD 300 makes you understand your materials like never before, being able to measure:

Advancements in automation are changing our industries – and the Wafer XRD 300 is leading the charge as a practical, powerful solution to manage orientation measurements at unprecedented speeds.

Wafer XRD 300 offers unparalleled efficiency and versatility for production quality control giving you highly accurate results in under 10 seconds.

It is well-suited for 300mm production enviroments where integration into custom automation is key.

| Sample throughput | 10000+ Wafer per Month |

|---|---|

| Geometry | On request |

| Precision | Tilt precision: 0.003 |

| XRD axis vs notch / flat position | 0.03° |

Version number: 1

Please contact support for the latest software version.

The ultimate solution for automated wafer sorting, crystal orientation, and much more – with the power to super-charge your productivity and futureproof your processes.