Spraytec remote control user manual (English)

Version number: MAN0399-02-EN-00

Looking for more information?

To request a quote, more information or download a brochure select an option below.

Malvern Panalytical's Spraytec laser diffraction system allows measurement of spray particle and spray droplet size distributions in real-time for more efficient product development of sprays and aerosols.

It has been specifically designed to address the unique requirements for spray characterization and deliver robust, reproducible droplet size data.

Incorporating over 35 years of experience in spray applications, Malvern Panalytical's Spraytec provides the data required to fully understand spray and atomization processes.

Measure across a wide size range (0.1-2000 μm) without requiring constant optics changes

Resolve rapid changes in droplet size over time: measure up to 10,000 measurements a second

Deliver accurate, concentration-independent results using a patented multiple scattering analysis

Characterize wide spray plumes without risking optical contamination

Reveal dynamic changes in spray particle size through unique size history analysis software

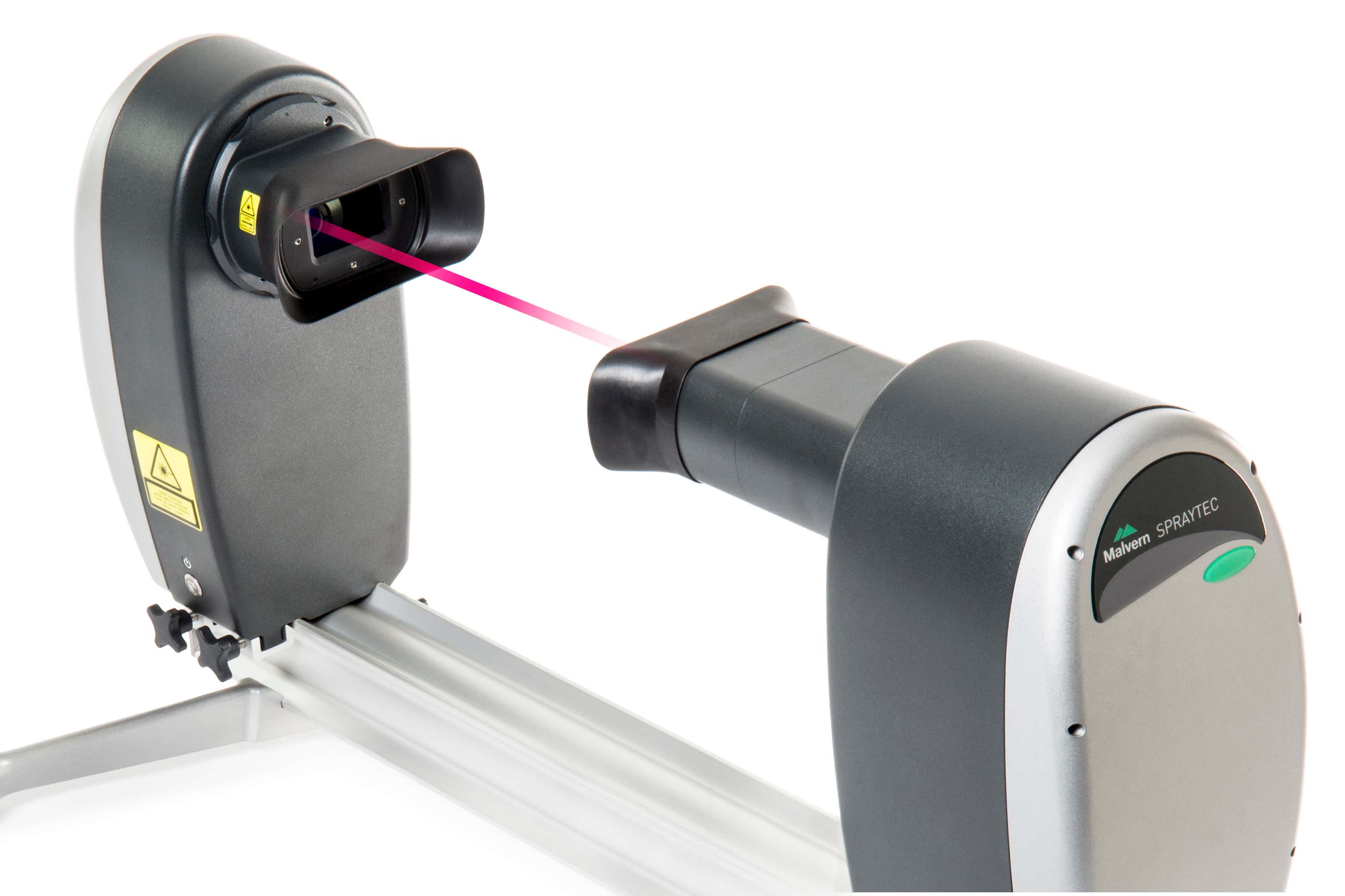

Spraytec uses laser diffraction for measuring the size of spray droplets and spray particles. It does this by measuring the intensity of light scattered as a laser beam passes through a spray. This data is analyzed to calculate the size of the droplets that created the scattering pattern. Spraytec is made up of the following main elements:

A transmitter module that contains the collimated laser light source used to illuminate the spray during a measurement.

A receiver module that can hold one of two lenses (300mm or 750mm), which focuses any light scattered by the spray onto a series of detectors. These detectors accurately measure the intensity of light scattered by the spray droplets over a wide range of angles.

An optical bench that ensures the transmitter and receiver are aligned. The length of this can be changed in order to fit with different applications, with the longest bench being 2.5m long.

The Spraytec software, which controls the system during the measurement process and analyzes the scattering data to calculate spray size distributions. The results are displayed as a ‘size history’ trend plot, allowing any changes in the droplet size over time to be instantly recognized.

The flexibility of the Spraytec system makes it ideally suited to applications across a wide range of industries, from fundamental research and development through to product quality control and batch release testing.

It delivers accurate, reproducible spray size analysis in an easy-to- understand format, improving product understanding and control.

Particle size is a key parameter in defining the deposition pattern and bioavailability of drug materials delivered using pump sprays and inhalers to the nasal mucosa and respiratory system. The Spraytec system can chart the changes in size produced during single device actuations, allowing the dynamics of particle dispersion to be identified along with the device reproducibility. Formulations can therefore be rapidly screened for the correct spray properties, reducing development times and improving drug delivery efficacy

Watch the webinar: Nasal Spray Drug Delivery

Measurement of the droplet size produced by atomizer systems is key in promoting process understanding and a knowledge of the environmental impact of spraying, for instance in coatings or agrochemical applications.

The Spraytec’s rugged design, efficient air purge and multiple scattering analysis ensures measurements can be made at high concentrations directly within a spray plume, providing the real-time data required to track changes in particle size during atomizer operation.

Application note: Characterizing spray nozzles for targeted agrochemical application

The Spraytec’s ability to measure at 10 kHz enables resolution of the fluctuations in droplet size observed during the rapid firing of automotive fuel injector systems. Provision of flexible triggering options ensures each injection event is fully captured. The repeatability of atomization can then be assessed and related to combustion efficiency.

Application note: Characterization of fuel injectors using high speed laser diffraction droplet size measurements

After using and analyzing my spray, I found Spraytec one of the best, most effective and easiest ways to characterize my spray. The Spraytec gives accurate and perfect results for the measurement of droplet size of spray. Moreover, it is very easy and safe to use, the laser is not so strong, so it doesn't effect you at all. Thank you Malvern Panalytical for such a great product.

Rizwan Minhas — LEGI Laboratory

| Principle | Laser Light Scattering |

|---|---|

| Analysis | Mie and Fraunhofer scattering including a patented multiple scattering analysis |

| Data acquisition rate | Rapid mode: 10kHz. Continuous mode: 1Hz |

| Maximum Measurement Time | Rapid mode: 30 seconds. Continuous mode: 60 minutes |

| Measurement Triggering | Internal: Based on transmission or light scattering levels. External: Based on TTL input or simple switch trigger |

| External Device Synchronization | Via 2 TTL trigger outputs |

| Light source | Max 4mW He-Ne Laser, 632.8nm |

|---|---|

| Lens arrangement | Fourier (parallel beam) |

| Lens Focal Length | 300mm and 750mm |

| Measurement range | 150mm at 0.5 µm, extending to greater than 1m above 5 µm |

| Arrangement | 36 element log-spaced array |

|---|---|

| Angular range | 0.015 – 17° ** |

| Alignment | Automatic |

| Particle size | 300mm lens: 0.1 – 900 µm (Dv50: 0.5 – 600 µm)

750mm lens: 2 – 2000 µm (Dv50: 5 – 1600 µm) |

|---|---|

| Accuracy | >1%*** |

| Repeatability | >1%*** |

| Reproducibility | >1%*** |

| 21 CFR part 11 | Enables an operating mode that assists with ER/ES compliance |

|---|

| Laser safety | Class 3R, IEC60825-1:2007 and CFR Chapter 1: Sub-chapter J: Part 1040 (CDRH) |

|---|---|

| Regulatory testing | CE / FCC compliant. Meets requirements of the European Low Voltage directive |

| Laboratory systems | 950mm optical bench: 950 x 550 x 610 mm (36kg)

1400mm optical bench: 37kg 1400 x 550 x 610 mm (37kg) |

|---|---|

| Spray Facility Systems | 950mm optical bench: 950 x 550 x 610 mm (36kg)

1400mm optical bench: 37kg 1400 x 550 x 610 mm (37kg) |

| Power | 100/240 v, 50/60 Hz |

|---|---|

| Product storage temperature | -20°C to +50 °C |

| Operating temperature (°C) | +15°C to +40°C |

| Humidity | 80% maximum for temperatures up to 31 °C, decreasing linearly to 50% at 40 °C

Non-condensing |

| Ingress Protection (IP) rating | IP65 when in normal use |

Version number: MAN0399-02-EN-00

Version number: MAN0571-02-FR

Version number: MAN0571-02-EN

Version number: MAN0369-3-0

Version number: MAN0368-3-0

Version number: MAN0571-01-DE-01

Version number: 006369-DOC-REVA1

Version number: 006373-DOC-REVA1

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Malvern Panalytical's Spraytec laser diffraction system allows measurement of spray particle and spray droplet size distributions in real-time for more efficient product development of sprays and aerosols.

It has been specifically designed to address the unique requirements for spray characterization and deliver robust, reproducible droplet size data.

Incorporating over 35 years of experience in spray applications, Malvern Panalytical's Spraytec provides the data required to fully understand spray and atomization processes.

Measure across a wide size range (0.1-2000 μm) without requiring constant optics changes

Resolve rapid changes in droplet size over time: measure up to 10,000 measurements a second

Deliver accurate, concentration-independent results using a patented multiple scattering analysis

Characterize wide spray plumes without risking optical contamination

Reveal dynamic changes in spray particle size through unique size history analysis software

Spraytec uses laser diffraction for measuring the size of spray droplets and spray particles. It does this by measuring the intensity of light scattered as a laser beam passes through a spray. This data is analyzed to calculate the size of the droplets that created the scattering pattern. Spraytec is made up of the following main elements:

A transmitter module that contains the collimated laser light source used to illuminate the spray during a measurement.

A receiver module that can hold one of two lenses (300mm or 750mm), which focuses any light scattered by the spray onto a series of detectors. These detectors accurately measure the intensity of light scattered by the spray droplets over a wide range of angles.

An optical bench that ensures the transmitter and receiver are aligned. The length of this can be changed in order to fit with different applications, with the longest bench being 2.5m long.

The Spraytec software, which controls the system during the measurement process and analyzes the scattering data to calculate spray size distributions. The results are displayed as a ‘size history’ trend plot, allowing any changes in the droplet size over time to be instantly recognized.

The flexibility of the Spraytec system makes it ideally suited to applications across a wide range of industries, from fundamental research and development through to product quality control and batch release testing.

It delivers accurate, reproducible spray size analysis in an easy-to- understand format, improving product understanding and control.

Particle size is a key parameter in defining the deposition pattern and bioavailability of drug materials delivered using pump sprays and inhalers to the nasal mucosa and respiratory system. The Spraytec system can chart the changes in size produced during single device actuations, allowing the dynamics of particle dispersion to be identified along with the device reproducibility. Formulations can therefore be rapidly screened for the correct spray properties, reducing development times and improving drug delivery efficacy

Watch the webinar: Nasal Spray Drug Delivery

Measurement of the droplet size produced by atomizer systems is key in promoting process understanding and a knowledge of the environmental impact of spraying, for instance in coatings or agrochemical applications.

The Spraytec’s rugged design, efficient air purge and multiple scattering analysis ensures measurements can be made at high concentrations directly within a spray plume, providing the real-time data required to track changes in particle size during atomizer operation.

Application note: Characterizing spray nozzles for targeted agrochemical application

The Spraytec’s ability to measure at 10 kHz enables resolution of the fluctuations in droplet size observed during the rapid firing of automotive fuel injector systems. Provision of flexible triggering options ensures each injection event is fully captured. The repeatability of atomization can then be assessed and related to combustion efficiency.

Application note: Characterization of fuel injectors using high speed laser diffraction droplet size measurements

After using and analyzing my spray, I found Spraytec one of the best, most effective and easiest ways to characterize my spray. The Spraytec gives accurate and perfect results for the measurement of droplet size of spray. Moreover, it is very easy and safe to use, the laser is not so strong, so it doesn't effect you at all. Thank you Malvern Panalytical for such a great product.

Rizwan Minhas — LEGI Laboratory

| Principle | Laser Light Scattering |

|---|---|

| Analysis | Mie and Fraunhofer scattering including a patented multiple scattering analysis |

| Data acquisition rate | Rapid mode: 10kHz. Continuous mode: 1Hz |

| Maximum Measurement Time | Rapid mode: 30 seconds. Continuous mode: 60 minutes |

| Measurement Triggering | Internal: Based on transmission or light scattering levels. External: Based on TTL input or simple switch trigger |

| External Device Synchronization | Via 2 TTL trigger outputs |

| Light source | Max 4mW He-Ne Laser, 632.8nm |

|---|---|

| Lens arrangement | Fourier (parallel beam) |

| Lens Focal Length | 300mm and 750mm |

| Measurement range | 150mm at 0.5 µm, extending to greater than 1m above 5 µm |

| Arrangement | 36 element log-spaced array |

|---|---|

| Angular range | 0.015 – 17° ** |

| Alignment | Automatic |

| Particle size | 300mm lens: 0.1 – 900 µm (Dv50: 0.5 – 600 µm)

750mm lens: 2 – 2000 µm (Dv50: 5 – 1600 µm) |

|---|---|

| Accuracy | >1%*** |

| Repeatability | >1%*** |

| Reproducibility | >1%*** |

| 21 CFR part 11 | Enables an operating mode that assists with ER/ES compliance |

|---|

| Laser safety | Class 3R, IEC60825-1:2007 and CFR Chapter 1: Sub-chapter J: Part 1040 (CDRH) |

|---|---|

| Regulatory testing | CE / FCC compliant. Meets requirements of the European Low Voltage directive |

| Laboratory systems | 950mm optical bench: 950 x 550 x 610 mm (36kg)

1400mm optical bench: 37kg 1400 x 550 x 610 mm (37kg) |

|---|---|

| Spray Facility Systems | 950mm optical bench: 950 x 550 x 610 mm (36kg)

1400mm optical bench: 37kg 1400 x 550 x 610 mm (37kg) |

| Power | 100/240 v, 50/60 Hz |

|---|---|

| Product storage temperature | -20°C to +50 °C |

| Operating temperature (°C) | +15°C to +40°C |

| Humidity | 80% maximum for temperatures up to 31 °C, decreasing linearly to 50% at 40 °C

Non-condensing |

| Ingress Protection (IP) rating | IP65 when in normal use |

Version number: MAN0399-02-EN-00

Version number: MAN0571-02-FR

Version number: MAN0571-02-EN

Version number: MAN0369-3-0

Version number: MAN0368-3-0

Version number: MAN0571-01-DE-01

Version number: 006369-DOC-REVA1

Version number: 006373-DOC-REVA1

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Incorporating over 30 years' know-how into one user-friendly instrument for rapid spray particle or droplet analysis data.