Epsilon 4 Pre-installation manual

Version number: 4

Access support to accelerate your scientific discovery with grants of up to $20K or $50K, or up to 50% off. Apply to our Academic Grant Program now

Apply to our Academic Grant Program now

Looking for more information?

To request a quote, more information or download a brochure select an option below.

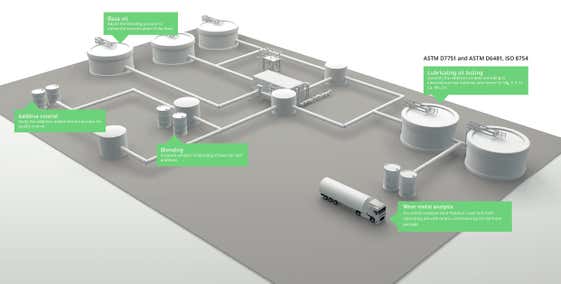

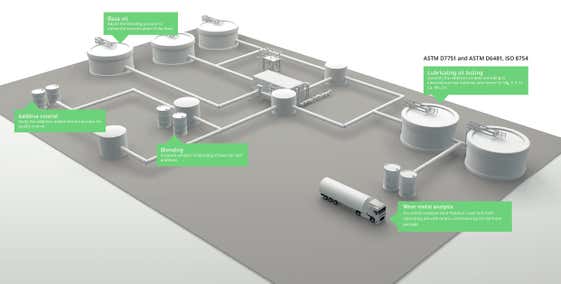

Speeding up engine test while maintaining product quality are essential industry requirement for producers of lubricating oils. Compliance to international test methods like ISO and ASTM is an essential industry requirement for elemental analysis of lubricating oils. For the Epsilon 4 this mandated compliancy is merely the starting point, but where the instrument really shines is the additional value it brings for many other analytical tasks in the production of lubricating oils. For example:

All analyses performed by Epsilon 4 comply with the latest test methods and norms, like ASTM D7751 and ASTM D6481.

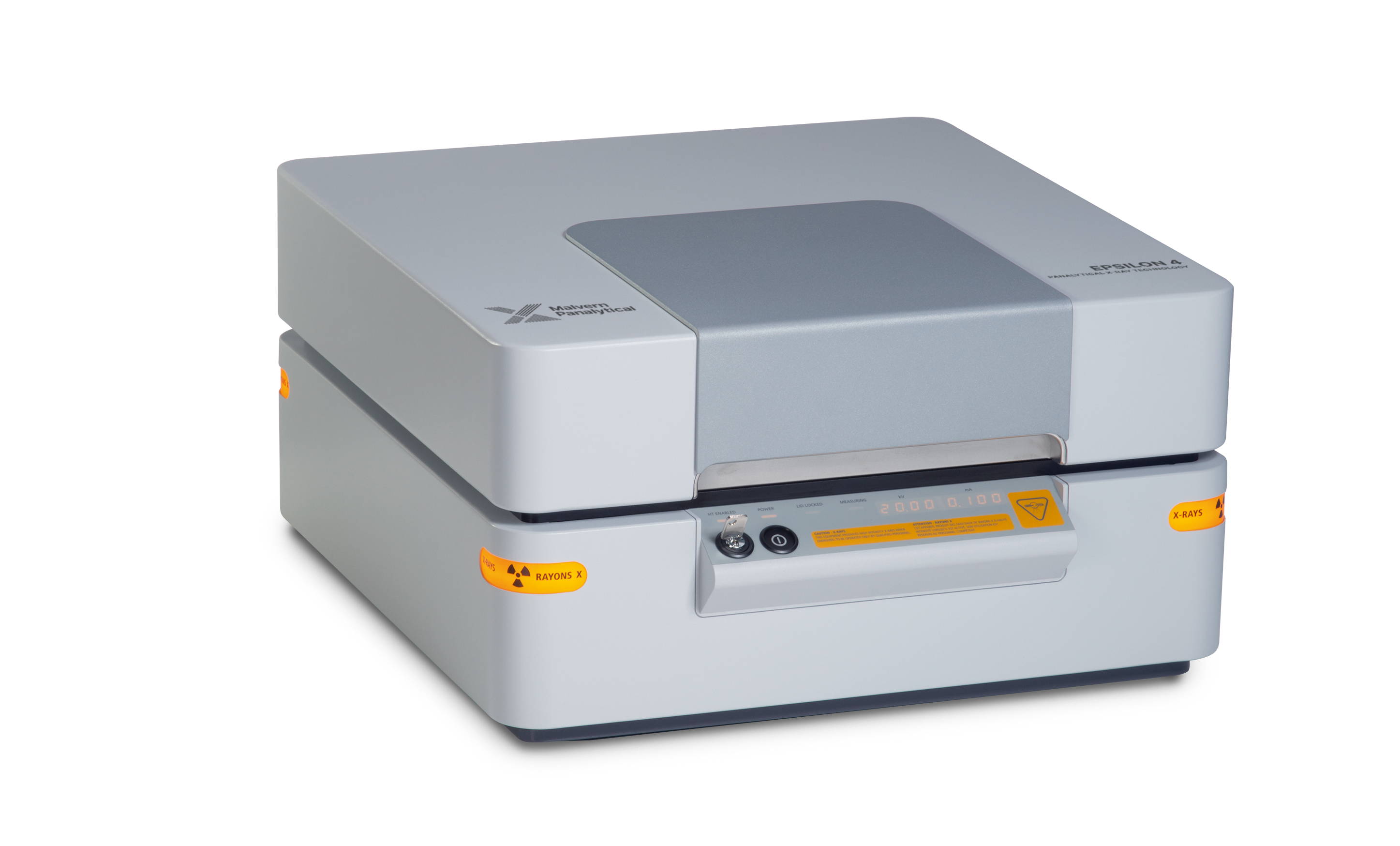

The power of benchtop XRF: Combining the latest excitation and detection technologies and smart design, the analytical performance of Epsilon 4 approaches that of more powerful and floor-standing spectrometers. Selective excitation and careful matching of the X-ray tube output to the capabilities of the detection system underlie the system’s outstanding performance.

Calibrated for years: A low-drift X-ray tube and an automatic drift correction system give compliant results for years without the need for re-calibration. This results in a more efficient use of the system and less cost of calibration maintenance.

Fast and sensitive: Fast measurements are achieved by using the latest silicon drift detector technology that produces significantly higher intensities. Unique detector electronics enable a linear count rate capacity to over 1,500,000 cps (at 50% dead time) and a count rate independent resolution typically better than 135 eV for better separation of analytical lines in the spectrum. This allows the Epsilon 4 spectrometer to run at full power and therefore realizes a much higher sample throughput compared to traditional EDXRF benchtop instruments.

Reduce helium consumption: The high performance of Epsilon 4 enables many applications to be operated in air atmosphere, without longer overhead time and costs involved for helium or maintenance of vacuum system. When measuring in air, low-energy X-ray photons characteristic of sodium, magnesium and aluminium, are sensitive to variations in air pressure and temperature. Built-in temperature and air-pressure sensors compensate for these environmental variations, ensuring excellent results whatever the weather.

Epsilon 4 offers excellent performance for elemental analysis in different processes in refineries.

This new and powerful benchtop XRF instrument is well suited for the analysis of additives and wear metals in lubricating oils according to the latest relevant international test methods.

Epsilon 4 is a star-performing benchtop XRF instrument and is well suited for the analysis of additives and wear metals in fresh and unused lubricating oils. The benchtop XRF instrument provides a fast method for the analysis of lubricating oils without the need for sample preparation and use of chemicals.

Epsilon 4 complies with the latest test method ASTM D7751-15 for the analysis of magnesium, phosphorus, sulfur, chlorine, calcium, zinc and molybdenum in fresh lubricating oil by XRF.

Epsilon 4 spectrometers can handle a large variety of sample types, weighing from a few milligrams to larger bulk samples. Samples can be measured as:

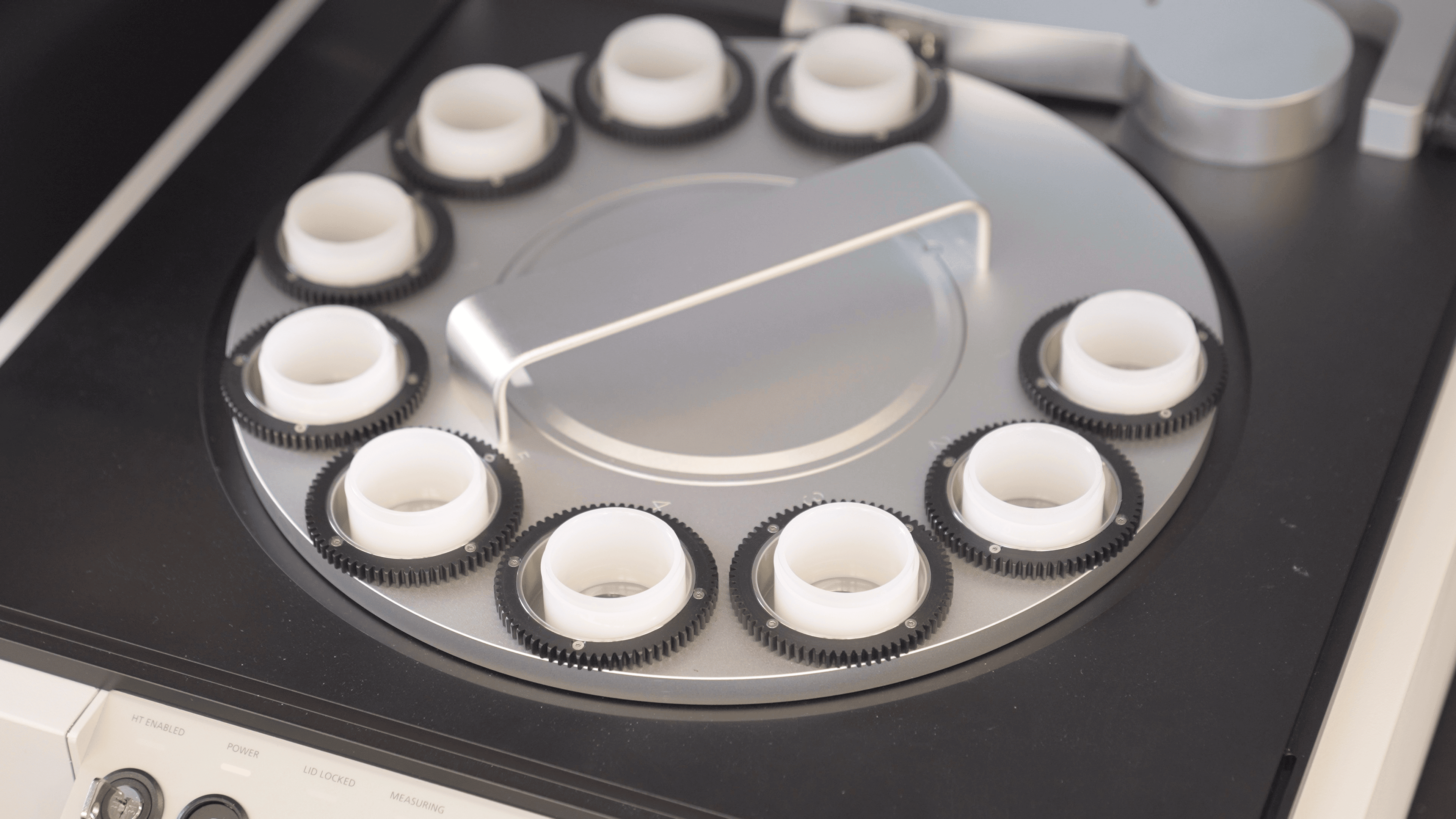

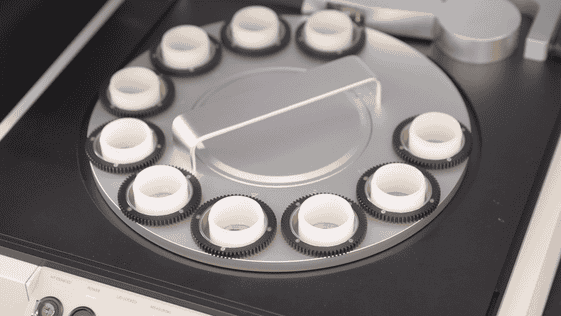

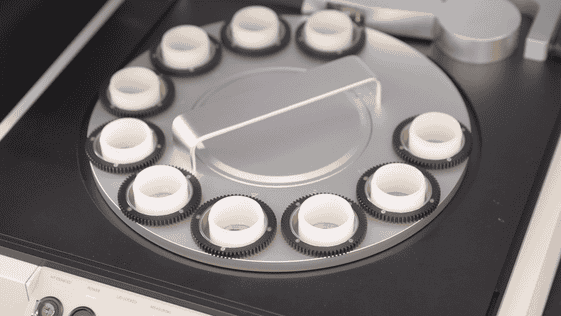

| Sample capacity | 10-position removable sample changer |

|---|---|

| Sample size | Typically 5 ml liquid samples |

| Features | Spinner is included for better accuracy of air filter analysis |

| Features | Metal-ceramic side window for maximum stability

50 micrometers thin beryllium window for high sensitivity for light elements (Na, Mg, Al, Si) |

|---|---|

| Tube setting | Ag anode X-ray tube for best performance of P, S and Cl analysis |

| Detector type | High-resolution silicon drift detector (SDD), typically 135 eV @ Mn-Kα |

|---|---|

| Features | Max count rate of 1,500,000 counts/s at 50% dead time

Thin-entrance detector window for high sensitivity |

| Software |

|

|---|

Version number: 4

Version number: 4

Version number: 4

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 1

Please contact support for the latest software version.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Speeding up engine test while maintaining product quality are essential industry requirement for producers of lubricating oils. Compliance to international test methods like ISO and ASTM is an essential industry requirement for elemental analysis of lubricating oils. For the Epsilon 4 this mandated compliancy is merely the starting point, but where the instrument really shines is the additional value it brings for many other analytical tasks in the production of lubricating oils. For example:

All analyses performed by Epsilon 4 comply with the latest test methods and norms, like ASTM D7751 and ASTM D6481.

The power of benchtop XRF: Combining the latest excitation and detection technologies and smart design, the analytical performance of Epsilon 4 approaches that of more powerful and floor-standing spectrometers. Selective excitation and careful matching of the X-ray tube output to the capabilities of the detection system underlie the system’s outstanding performance.

Calibrated for years: A low-drift X-ray tube and an automatic drift correction system give compliant results for years without the need for re-calibration. This results in a more efficient use of the system and less cost of calibration maintenance.

Fast and sensitive: Fast measurements are achieved by using the latest silicon drift detector technology that produces significantly higher intensities. Unique detector electronics enable a linear count rate capacity to over 1,500,000 cps (at 50% dead time) and a count rate independent resolution typically better than 135 eV for better separation of analytical lines in the spectrum. This allows the Epsilon 4 spectrometer to run at full power and therefore realizes a much higher sample throughput compared to traditional EDXRF benchtop instruments.

Reduce helium consumption: The high performance of Epsilon 4 enables many applications to be operated in air atmosphere, without longer overhead time and costs involved for helium or maintenance of vacuum system. When measuring in air, low-energy X-ray photons characteristic of sodium, magnesium and aluminium, are sensitive to variations in air pressure and temperature. Built-in temperature and air-pressure sensors compensate for these environmental variations, ensuring excellent results whatever the weather.

Epsilon 4 offers excellent performance for elemental analysis in different processes in refineries.

This new and powerful benchtop XRF instrument is well suited for the analysis of additives and wear metals in lubricating oils according to the latest relevant international test methods.

Epsilon 4 is a star-performing benchtop XRF instrument and is well suited for the analysis of additives and wear metals in fresh and unused lubricating oils. The benchtop XRF instrument provides a fast method for the analysis of lubricating oils without the need for sample preparation and use of chemicals.

Epsilon 4 complies with the latest test method ASTM D7751-15 for the analysis of magnesium, phosphorus, sulfur, chlorine, calcium, zinc and molybdenum in fresh lubricating oil by XRF.

Epsilon 4 spectrometers can handle a large variety of sample types, weighing from a few milligrams to larger bulk samples. Samples can be measured as:

| Sample capacity | 10-position removable sample changer |

|---|---|

| Sample size | Typically 5 ml liquid samples |

| Features | Spinner is included for better accuracy of air filter analysis |

| Features | Metal-ceramic side window for maximum stability

50 micrometers thin beryllium window for high sensitivity for light elements (Na, Mg, Al, Si) |

|---|---|

| Tube setting | Ag anode X-ray tube for best performance of P, S and Cl analysis |

| Detector type | High-resolution silicon drift detector (SDD), typically 135 eV @ Mn-Kα |

|---|---|

| Features | Max count rate of 1,500,000 counts/s at 50% dead time

Thin-entrance detector window for high sensitivity |

| Software |

|

|---|

Version number: 4

Version number: 4

Version number: 4

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 3

Version number: 1

Please contact support for the latest software version.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Value beyond compliance: powerful benchtop XRF, ideal for analysis of additives and wear metals in lubricating oils.