X'Pert³ MRD XL Pre-installation manual (English)

Version number: 6

X'Pert³ is now a Smart Instrument!. Find out more

Find out more

Looking for more information?

To request a quote, more information or download a brochure select an option below.

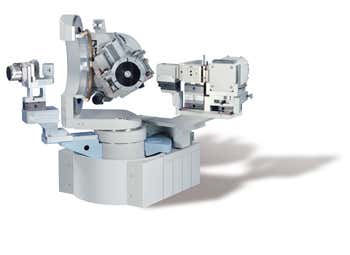

The long and successful history of Malvern Panalytical's Materials Research Diffractometers (MRD) continues with the generation of X’Pert³ MRD XL.

The improved performance and reliability of the new platform have added more analytical capability and power for X-ray scattering studies in:

The X’Pert³ MRD XL handles a wide range of applications with full wafer mapping up to 200 mm.

The X'Pert³ MRD systems offer advanced and innovative X-ray diffraction solutions from research to process development and process control.

These technologies make all systems field-upgradable to all existing options and new developments in hardware and software to come.

The X'Pert³ Extended MRD (XL) brings increased versatility to the range of X'Pert³ MRD systems. An extra PreFIX mounting platform allows mounting of an X-ray mirror and a high-resolution monochromator in-line, significantly increasing the intensity of the incident beam.

You can benefit from increased application versatility without compromise on data quality, high-resolution X-ray diffraction with high intensities, shorter measurement times for measurements such as reciprocal space mapping and rebuild from standard to extended configuration in minutes thanks to the PreFIX concept. With the 2nd generation PreFIX, reconfiguring is easy and optics positioning is more accurate than ever.

With the X'Pert³ MRD (XL) system for in-plane diffraction, it becomes possible to measure diffraction from lattice planes that are perpendicular to the sample surface.

Standard and in-plane geometries on one system and a wide range of diffraction experiments on polycrystalline and highly perfect thin films, are just two of many benefits.

Download the brochure: Semiconductor wafers - Crystalline quality

The Malvern Panalytical X’Pert³ MRD and MRD XL are all-in-one X-ray solution systems that can be used in many industry applications, including:

Whether for growth studies or device design, the measurement of layer quality, thickness, strain and alloy composition using high-resolution XRD has been at the heart of research and development in electronic and optoelectronic multilayer semiconductor devices. With a choice of X-ray mirrors, monochromators and detectors, the X’Pert3 MRD and MRD XL offer high-resolution configurations to suit different materials systems ranging from lattice-matched semiconductors, through relaxed buffer layers on to novel exotic layers on non-standard substrates

Polycrystalline layers and coatings are an important component of many thin films and multilayer devices. The evolution of polycrystalline layer morphology during deposition is a key study area in functional materials research and development. X’Pert3 MRD and X’Pert3 MRD XL can be fully equipped with a range of slits, parallel beam X-ray mirror, polycapillary lens, crossed slits and monocapillaries to give the full choice of incident beam optics for reflectometry, stress, texture and phase ID.

Functional devices may contain disordered, amorphous or nanocomposite thin films. The flexibility of the X’Pert3 MRD and MRD XL systems allows for the incorporation of multiple analytical methods. A range of high-resolution optics, slits and parallel plate collimators are available to give the optimum performance for grazing incidence methods, in-plane diffraction and reflectometry.

Studying the behavior of materials under a variety of conditions is an essential part of materials research and process development. The X’Pert3 MRD and MRD XL are designed for the easy incorporation of the DHS1100 non-ambient sample stage from Anton Paar, enabling automated measurements under a range of temperatures and inert atmosphere

Instrument gives excellent accuracy and is of good quality.Good intensity and rapid performance. It is easy to operate.

Yifan Zheng — Zhejiang University of Technology

| Dimensions | 1370 (w) x 1131 (d) x 1972 (h) mm

The system is on wheels for easy installation and relocation |

|---|---|

| Weight | 1150 kg |

| Type | Horizontal goniometer |

|---|---|

| Radius | 420 mm |

| Range | -40°< 2θ <160° (depending on accessories) |

| Accuracy | Long range accuracy ±0.0025°

Short range (0.5°) accuracy ±0.0004°

|

| Reproducibility | < 0.0002°

|

| Features | Fully ceramic X-ray tubes manufactured by Malvern Panalytical’s specialized factory under cleanroom conditions

Tool free swap of line to point focus

3 kW generator supporting all current and future X-ray tubes

Hybrid pixel detectors with smallest pixel size (55 x 55 µm2) available on the market

5-axes cradle with 200 x 200 mm2 x, y translation |

|---|---|

| Rotation | Chi rotation ±92°

Phi rotation 2 x 360° |

| Smallest addressable increment | 0.0001° |

Unleash the potential of your data

Until now, instrument data has too often been stuck in manual records, spreadsheets or site-specific servers. By connecting the X'Pert3 to our Smart Manager and continually analyzing instrument data in the cloud, you can unleash its full potential. This is just one of our digital solutions that are part of Malvern Panalytical's Smart Manager.

Version number: 6

Version number: 7

Version number: 2

Version number: 4

Version number: 4

Version number: 3

Version number: 10

Version number: 9

Version number: 4

Version number: 7

Version number: 4

Please contact support for the latest software version.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

The long and successful history of Malvern Panalytical's Materials Research Diffractometers (MRD) continues with the generation of X’Pert³ MRD XL.

The improved performance and reliability of the new platform have added more analytical capability and power for X-ray scattering studies in:

The X’Pert³ MRD XL handles a wide range of applications with full wafer mapping up to 200 mm.

The X'Pert³ MRD systems offer advanced and innovative X-ray diffraction solutions from research to process development and process control.

These technologies make all systems field-upgradable to all existing options and new developments in hardware and software to come.

The X'Pert³ Extended MRD (XL) brings increased versatility to the range of X'Pert³ MRD systems. An extra PreFIX mounting platform allows mounting of an X-ray mirror and a high-resolution monochromator in-line, significantly increasing the intensity of the incident beam.

You can benefit from increased application versatility without compromise on data quality, high-resolution X-ray diffraction with high intensities, shorter measurement times for measurements such as reciprocal space mapping and rebuild from standard to extended configuration in minutes thanks to the PreFIX concept. With the 2nd generation PreFIX, reconfiguring is easy and optics positioning is more accurate than ever.

With the X'Pert³ MRD (XL) system for in-plane diffraction, it becomes possible to measure diffraction from lattice planes that are perpendicular to the sample surface.

Standard and in-plane geometries on one system and a wide range of diffraction experiments on polycrystalline and highly perfect thin films, are just two of many benefits.

Download the brochure: Semiconductor wafers - Crystalline quality

The Malvern Panalytical X’Pert³ MRD and MRD XL are all-in-one X-ray solution systems that can be used in many industry applications, including:

Whether for growth studies or device design, the measurement of layer quality, thickness, strain and alloy composition using high-resolution XRD has been at the heart of research and development in electronic and optoelectronic multilayer semiconductor devices. With a choice of X-ray mirrors, monochromators and detectors, the X’Pert3 MRD and MRD XL offer high-resolution configurations to suit different materials systems ranging from lattice-matched semiconductors, through relaxed buffer layers on to novel exotic layers on non-standard substrates

Polycrystalline layers and coatings are an important component of many thin films and multilayer devices. The evolution of polycrystalline layer morphology during deposition is a key study area in functional materials research and development. X’Pert3 MRD and X’Pert3 MRD XL can be fully equipped with a range of slits, parallel beam X-ray mirror, polycapillary lens, crossed slits and monocapillaries to give the full choice of incident beam optics for reflectometry, stress, texture and phase ID.

Functional devices may contain disordered, amorphous or nanocomposite thin films. The flexibility of the X’Pert3 MRD and MRD XL systems allows for the incorporation of multiple analytical methods. A range of high-resolution optics, slits and parallel plate collimators are available to give the optimum performance for grazing incidence methods, in-plane diffraction and reflectometry.

Studying the behavior of materials under a variety of conditions is an essential part of materials research and process development. The X’Pert3 MRD and MRD XL are designed for the easy incorporation of the DHS1100 non-ambient sample stage from Anton Paar, enabling automated measurements under a range of temperatures and inert atmosphere

Instrument gives excellent accuracy and is of good quality.Good intensity and rapid performance. It is easy to operate.

Yifan Zheng — Zhejiang University of Technology

| Dimensions | 1370 (w) x 1131 (d) x 1972 (h) mm

The system is on wheels for easy installation and relocation |

|---|---|

| Weight | 1150 kg |

| Type | Horizontal goniometer |

|---|---|

| Radius | 420 mm |

| Range | -40°< 2θ <160° (depending on accessories) |

| Accuracy | Long range accuracy ±0.0025°

Short range (0.5°) accuracy ±0.0004°

|

| Reproducibility | < 0.0002°

|

| Features | Fully ceramic X-ray tubes manufactured by Malvern Panalytical’s specialized factory under cleanroom conditions

Tool free swap of line to point focus

3 kW generator supporting all current and future X-ray tubes

Hybrid pixel detectors with smallest pixel size (55 x 55 µm2) available on the market

5-axes cradle with 200 x 200 mm2 x, y translation |

|---|---|

| Rotation | Chi rotation ±92°

Phi rotation 2 x 360° |

| Smallest addressable increment | 0.0001° |

Unleash the potential of your data

Until now, instrument data has too often been stuck in manual records, spreadsheets or site-specific servers. By connecting the X'Pert3 to our Smart Manager and continually analyzing instrument data in the cloud, you can unleash its full potential. This is just one of our digital solutions that are part of Malvern Panalytical's Smart Manager.

Version number: 6

Version number: 7

Version number: 2

Version number: 4

Version number: 4

Version number: 3

Version number: 10

Version number: 9

Version number: 4

Version number: 7

Version number: 4

Please contact support for the latest software version.

To assure that your instrument remains in top condition and performs on the highest level, Malvern Panalytical offers a wide range of services. Our expertise and support services assure an optimal functioning of your instrument.

Service for a lifetime

Adding value to your processes

Versatile XRD research & development. High intensities for shorter measurement times. A new generation of tools for your wafer analysis.