Pharmaceutical API development

Physicochemical analysis for data-driven early decision-making in pharmaceutical development

Physicochemical analysis for data-driven early decision-making in pharmaceutical development

A core part of drug development is the identification of APIs that retain their quality and efficiency when produced at scale. However, APIs that show promise during development can lose their efficiency when scaled-up. This happens for a variety of reasons, including chemical contaminants introduced during processing and the formation of alternate API polymorphs.

Detecting and quantifying these substances is vital to ‘win quick, fail fast’ approaches, enabling the rapid identification of developable APIs that meet safety, bioavailability, and processability requirements.

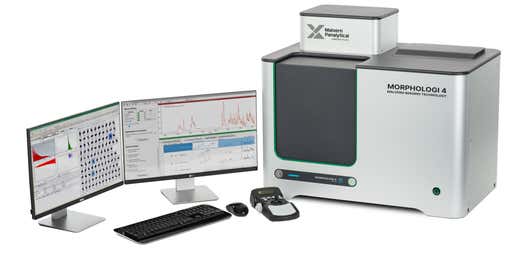

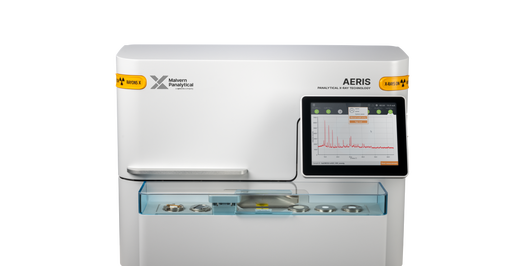

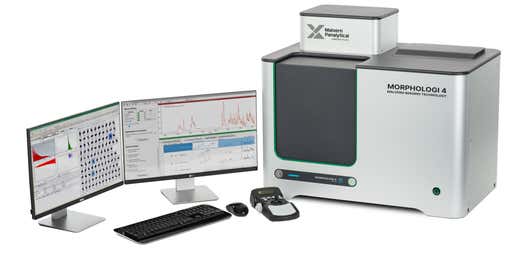

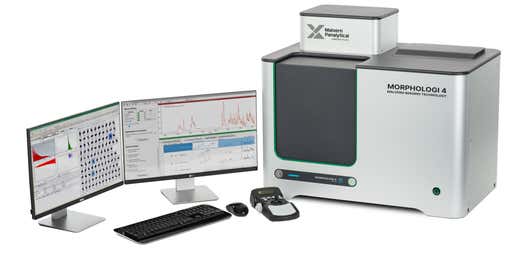

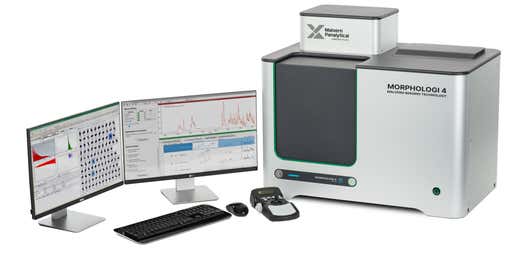

Malvern Panalytical has developed tried and tested methods and instruments that provide significant time and cost savings to our partners in the pharmaceutical sector. These instruments ensure that you have the insights needed to make informed decisions, improve processability, and aid scale-up.

Malvern Panalytical has a deep understanding of how to apply physicochemical analysis throughout the lifecycle of your API, from discovery, through scale-up and all the way to manufacturing. Our systems can help you answer questions about API bioavailability, stability, processability, and quality. They support:

Many APIs fail on scale-up due to issues with stability and/or processability. Malvern Panalytical systems provide insights that enable a QbD approach to API development, supporting robust design space definition, process optimization, and the maintenance of process performance within that space.

Malvern Panalytical’s systems help answer questions including:

The poor solubility of many APIs adds to the complexity of ensuring that a molecule has adequate bioavailability. Approaches such as the Developability Classification System (DCS) and Manufacturing Classification System (MCS) help identify molecules likely to meet bioavailability and scale-up requirements. These systems depend on physicochemical data to connect lead optimization and API salt & polymorph selection to the Critical Material Attributes (CMAs) necessary for meeting production needs.

Common strategies to enhance solubility in API design include reducing particle size, selecting different polymorphs, and using amorphous forms of the molecule. Malvern Panalytical’s systems help answer questions including:

Understanding the stability of solid-form APIs is crucial in lead optimization, salt screening, and process development. Polymorphic transitions can alter dissolution rates, reduce efficacy, and cause adverse reactions, potentially complicating patenting processes. It is therefore vital to select and confirm polymorphic stability, especially when using amorphous forms to enhance solubility, as unexpected crystallization can be detrimental. Knowing and understanding polymorphic behavior ensures API stability and mitigates risks associated with late-emerging polymorphs that could hinder downstream development.

Malvern Panalytical’s solutions help answer questions such as:

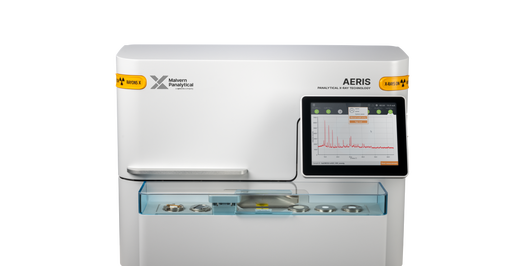

Eliminating elemental impurities in pharmaceutical products is essential for patient safety. Impurities introduced during processing must be removed throughout development, scale-up, and manufacturing. Access to precise elemental analysis methods is crucial for rapid process development and control.

Introducing X-ray fluorescence and morphological imaging into your workflow can help to accelerate your development processes and shorten your route to market significantly. Fast and non-destructive, these technologies provide robust screening solutions for the elemental purity of your API.

Malvern Panalytical’s solutions help answer questions such as:

Handover to manufacturing requires the definition of a robust Chemistry, Manufacturing, and Controls (CMC) package. This package must ensure that CMAs are monitored to maintain API product quality and safety. Microstructure and solid-form analysis are often key characterizations, in line with ICH guidance (ICH Q3D, ICH Q6A, and ICH Q1A).

Malvern Panalytical provides comprehensive solutions for instrument qualification and application in a validated (GxP) environment that can help support: