Laboratory Automation

Automated process control solutions

Automated process control solutions

Laboratory analysis plays a key role in many industries to ensure the quality and safety of the final product. From mining operations to the cement, pharmaceutical, and food industries. There is a constant need to optimize the quality and reliability of the analytical process, reduce operator dependencies and reduce staff, especially in areas where it is unsafe or difficult to attract the right personnel.

Malvern Panalytical has a dedicated team of process control and laboratory automation experts.

Our team of experts was founded more than 25 years ago, and has realized hundreds of laboratory automation solutions.

To add value to your processes, this experienced team offers a complete spectrum of laboratory automation and information systems including sample transportation, preparation, analysis and results processing.

Within an automated laboratory, complete sample preparation, analysis processes and sample transportation to and within the laboratory, can be automated. Results can be merged, validated and distributed with little or no human intervention. This leads to higher repeatability, smaller tolerances and lower costs for your analysis requirements.

Malvern Panalytical offers a full range of lab automation solutions tailored to the needs of the individual customer and designed in collaboration with the customer. This flexible approach ensures that we create a fully customized and optimized workflow together, maximizing the value created for your business.

Lab automation is becoming one of the major areas of progress toward industry 4.0, as our 270+ successful projects testify. Early-adopting customers gain a significant market advantage, thanks to gains in productivity and lowered running costs.

Our automated lab solutions have enabled many of our customers to achieve productivity, cost, and sustainability goals. Check out some of our successful collaborations below.

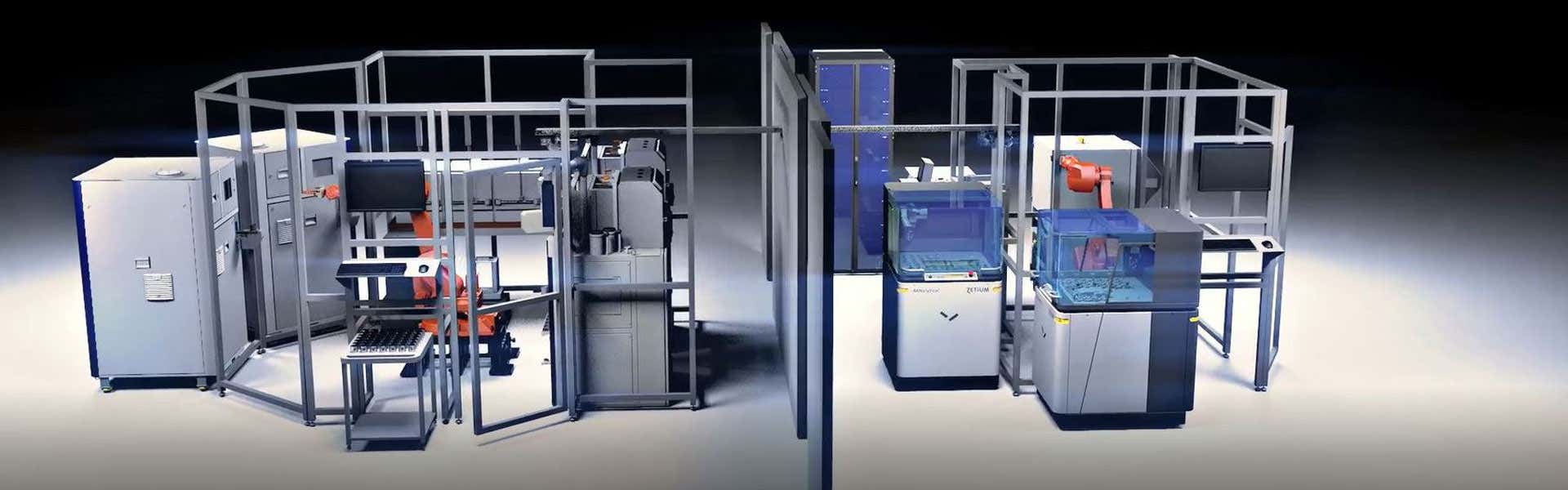

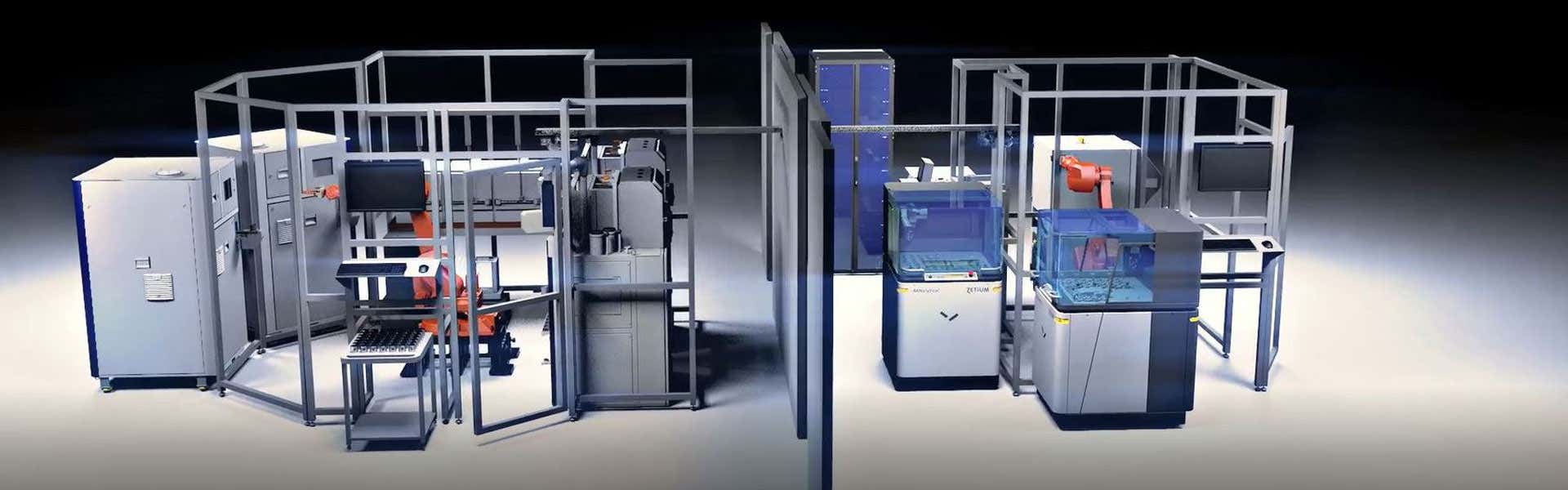

Automation setups vary from ‘single-line', with one preparation machine coupled to one analysis system, to comprehensive robot cell solutions where a number of preparation machines are coupled to multiple analysis systems in a redundant fashion, enhancing the uptime above 99%. Every automated laboratory solution is optimized to individual customer needs.

The entire analytical process can be automated, with the following steps included as part of a complete solution:

Thanks to our connected LIMS software SamTracs, all these processes are easily managed digitally. Malvern Panalytical’s OmniTrust software can also be implemented to streamline compliance into your laboratory workflow.

Malvern Panalytical works with selected expert partners chosen with the customer, taking into consideration everything that contributes to reliable service. This approach enables us to develop reliable and robust solutions, tailored to your individual needs, that deliver the best possible fit with your processes – and maximum value generation for your business.

Our innovative simulation suite offers a preview of the throughput statistics your chosen automation design will deliver. This helps you identify your highest priorities – and make well-informed decisions throughout the process.

You’ll be supported throughout the design and implementation of your automated lab by our process control experts. Their expertise often makes it possible to re-integrate older automated equipment into your new setup, keeping costs low.

Once your system is in place, we’ll provide 10 years’ support as standard – keeping your automated lab running at its best for many years to come through software updates and spare part replacements, plus support with any upgrades you choose.

AerisCompact benchtop X-ray diffractometers |

Epsilon XflowDirect insight into your liquid process parameters |

Epsilon XlineIn-line control for continuous roll-to-roll processes |

ZetiumHigh end floor-standing WDXRF spectrometers |

Axios FASTHigh throughput simultaneous WDXRF spectrometer |

Epsilon 4Fast and accurate at-line elemental analysis |

|

|---|---|---|---|---|---|---|

| Technology | ||||||

| X-ray Diffraction (XRD) | ||||||

| Energy Dispersive X-ray Fluorescence (EDXRF) | ||||||

| Wavelength Dispersive X-ray Fluorescence (WDXRF) | ||||||

| Laser Diffraction | ||||||

| Dynamic Light Scattering | ||||||

| Electrophoretic Light Scattering | ||||||