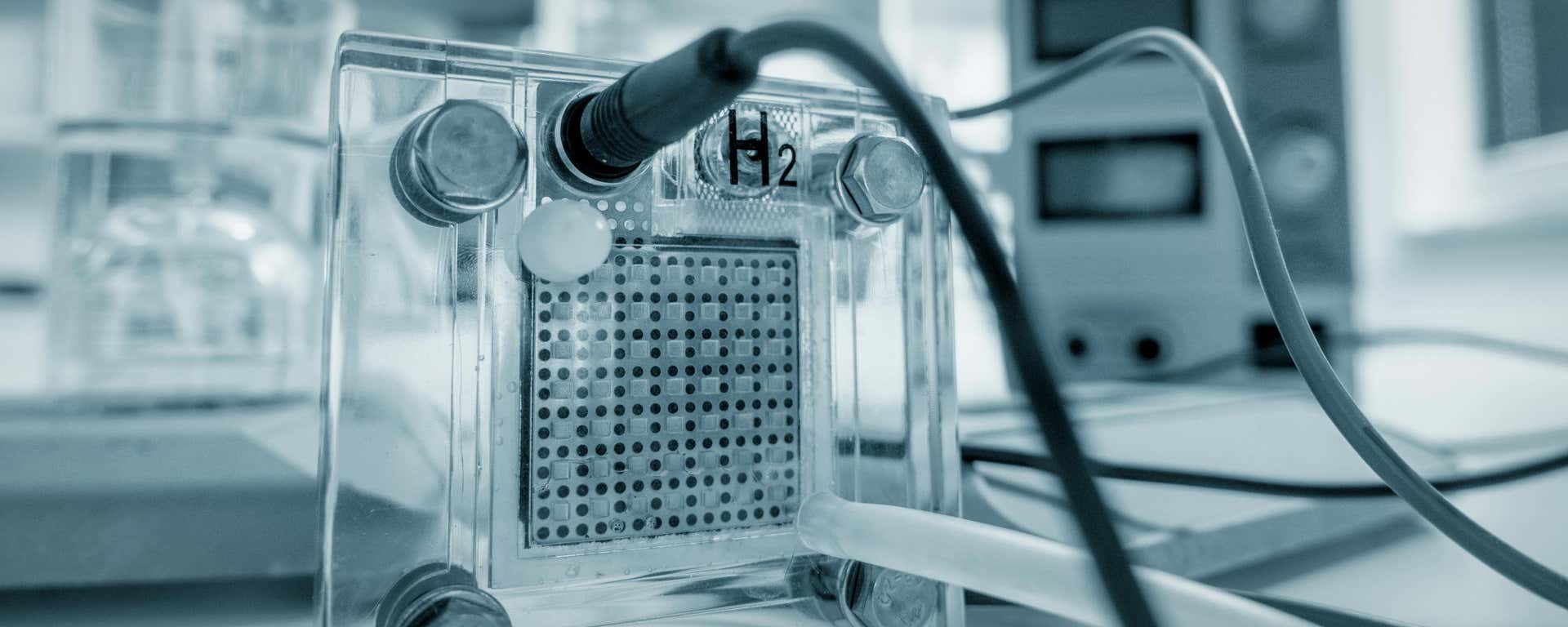

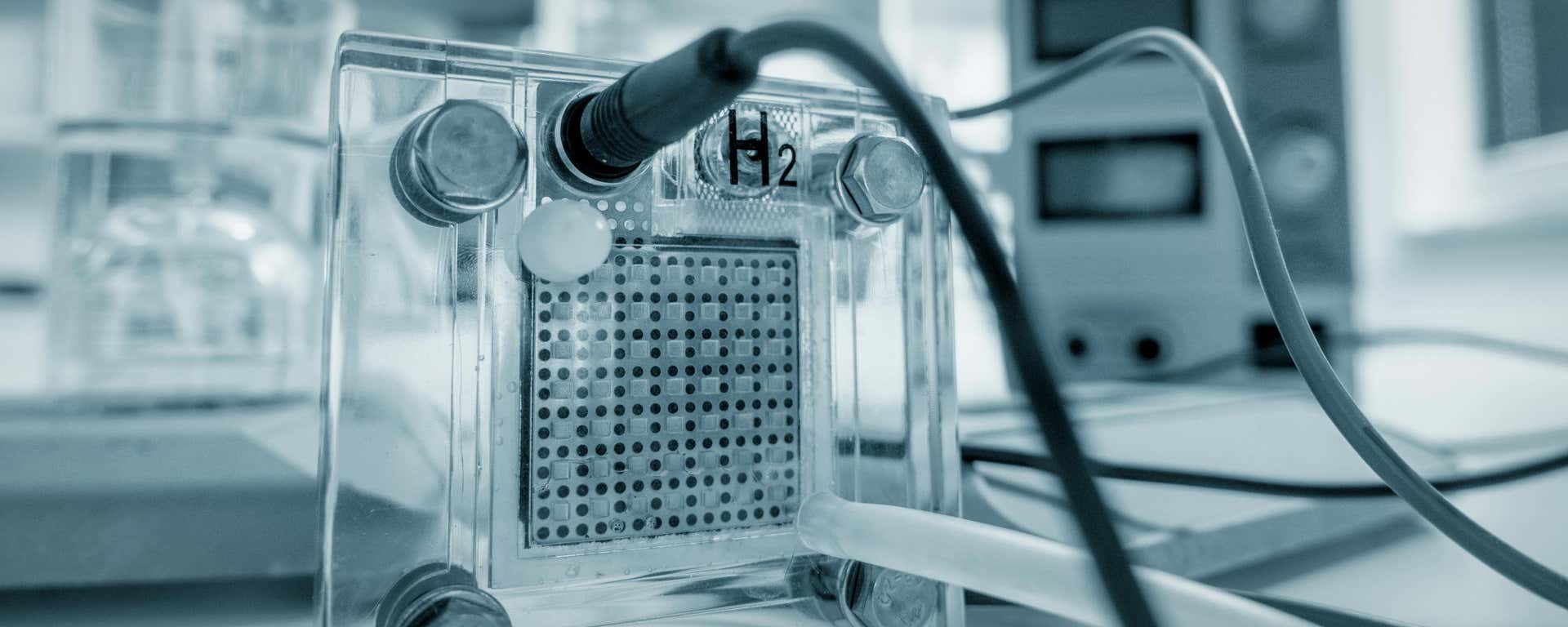

Hydrogen catalyst analysis

Hydrogen can significantly aid in decarbonization by serving as a clean energy carrier, reducing reliance on fossil fuels across various sectors:

Hydrogen supports over 60% of high GHG-emitting applications and is projected to contribute more than 20% of global carbon abatement by 2050, making it essential to a net-zero future.

Hydrogen catalysts are critical for enhancing the efficiency of hydrogen production, storage, and utilization. Their roles span several technologies:

Key components of a hydrogen-based economy are:

Technologies:

Materials:Adsorbents, membranes, catalysts

Measurement Goals:

Technologies

Hydrogen can be stored as:

Materials: Adsorbents, catalysts

Measurement Goals:

Technologies

Hydrogen is versatile:

Materials: Membranes, catalysts, adsorbents

Measurement Goals:

Small, powerful and portable XRF analyzer

High performance gas adsorption